Preservation Self-Assessment Program

Audiotape

Open Reel Audio

This sound format type consists of magnetized particles embedded on a plastic tape carrier. This format type is called "open reel" because the magnetic tape is not enclosed in a plastic cassette.

- ¼" Open Reel (c. 1935 - 1980s)

- 2" Open Reel (Late 1950s - 1980s)

- 1" Open Reel (Early 1950s - 1980s)

- ½" Open Reel (1950s - 1980s)

Cassette / Cartridge-Based Audio

This sound format type consists of magnetized particles embedded on a plastic tape carrier. The magnetic tape is contained within a plastic cassette or cartridge.

- Continuous Loop Cartridges (Cart) (1959 - late 1990s; popular use, 1950s – 1970s)

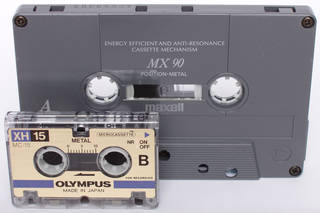

- Compact Cassette (1963 - present; popular use, 1970s - 1990s)

- 8-Track (1964 – early 1980s)

- Microcassette (1969 - present)

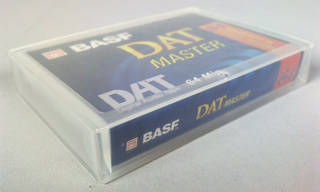

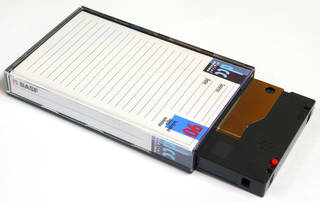

- Digital Audio Tape (DAT) (1987 – mid 2000s)

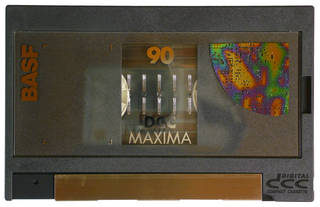

- Digital Compact Cassette (DCC) (1992 – late 1990s)

Related Notes

¼" Open Reel

- Dates

- c. 1935 – 1980s

- Common Size(s)

- Tape width: ¼"

- Reel diameter: 2"; 3"; 5"; 7"; 10.5"

- Description

- Quarter-inch open reel audio is the earliest type of magnetic tape-based recorded sound format. The tape is composed of magnetic particles, binder, and a base of either acetate, paper, polyester, or PVC. The quarter-inch size, which was the standard width of open reel tape until the 1950s, is the most common open reel tape width, particularly among amateur recordings. Cellulose acetate was the most common tape base during the 1940s and 1950s. Acetate bases can be differentiated from polyester bases by conducting a quick light test. Hold the reel up to a light source - if light "pipes" through, the base is most likely acetate. Reel size can vary, measuring from 2 or 3 inches to 10.5 inches in diameter (14-inch diameters are also possible), with 5, 7, and 10.5 inches being the most common sizes found in archives. The tape width is approximately ¼".

- Composition

- Magnetic tape (acetate, paper, polyester, or PVC) on a hub or reel

- Deterioration

-

Quarter-inch open reel audio is susceptible to risks associated with age, hardware, and equipment obsolescence. Like other types of magnetic media, it is prone to risks such as mold, binder deterioration, physical damage, signal drop-outs, and, in the case of acetate-based tapes, base deterioration. Quarter-inch tape may be thinner and more fragile than other kinds of tape, and it is more susceptible to stretching and breaking during playback.

Tapes should be wound tightly and evenly. An uneven tape pack can allow dirt to come in contact with and abrade the tape's surface and edges. Unevenly wound tapes can cause the tape to warp and lose its shape, which will affect playback sound quality. Tapes with thinner widths are more susceptible to information loss when the tape edge is damaged, as magnetic track configurations are smaller and placed more closely to the tape edge.

Tapes are also prone to blocking or pinning, which occurs when layers of tape adhere to adjacent layers. Blocking involves large sections of tape adhered together, while pinning involves small sections. Both blocking and pinning can result in loss of information by damaging the tape layers or by preventing playback.

- Risk Level

- Since magnetic media is a dying medium with a limited lifespan, these tapes should be reformatted based on the content value.

- Playback

- Reel-to-reel audio playback equipment and media are becoming scarce, although there are a few manufacturers that are still filling the needs of professional audio studios. In order to play back a tape properly, you must know the tape track configuration and recording speed. In addition to the proper playback head configuration, playback equipment must have a tape transport able to support the tape's full width in order to read all the tracks encoded on it. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- Patented first in 1928, open reel audiotape was first demonstrated to the public in 1935 in Germany. After World War II, it began to gain worldwide popularity and was further developed in the US by Ampex and EMI. Quarter-inch was the most common and affordable open reel width. Quarter-inch open reel tapes were used in home recording and other semi-pro and consumer markets. Prior to digital technology, ¼" open reel tape was considered the standard audio preservation medium. As analog tape and equipment are obsolete, digital capture has become the archival standard.

- Storage Environment

-

While some base variation for this format is possible, polyester is by far the most common, and guidelines are given assuming a polyester base. If nitrate or acetate base is suspected, colder storage is necessary. Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

The container should support the reel by the hub in order to both preserve the tape pack and prevent distortion of the tape. Use unslotted reels if possible. Acid-free archival hold-down tape should also be used to secure loose ends of the open reel tape.

Whenever feasible, replace original cardboard containers as they are typically non-archival (i.e. acidic) and have little or no hub support. An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- Store all magnetic tape vertically on end, inside its case. Stacking any tape format horizontally--or even allowing it to lean for too long--can compromise a tape pack and cause warping. Its container should provide hub support for the reel in order to preserve the pack and prevent distortion. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Never touch the surface of a magnetic tape recording. Handle by the hub instead. Do not pull on the tape or squeeze the reel flanges. This places stress on the tape, potentially causing distortion and damage. Never leave media in a playback machine; always return to storage enclosure when not in use.

2" Open Reel

- Synonyms

-

- Multitrack recording

- 24-track tape

- 16-track tape

- Dates

- Late 1950s – 1980s

- Common Size(s)

- Tape width: 2"

- Reel diameter: 3"; 5"; 7"; 10.5"; 14"

- Description

-

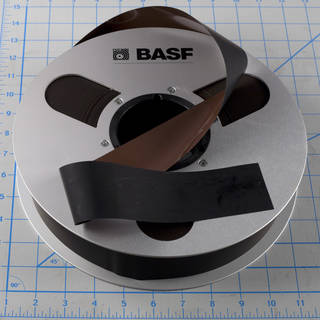

Two-inch open reel audio is a magnetic tape-based recorded sound format. The tape is composed of magnetic particles, binder, and a base of either acetate or polyester. Open reel tapes over ¼" were typically used in studio production (i.e. multitrack recording). A 2" tape, for instance, might contain as many as 24 audio tracks.

Acetate bases can be differentiated from polyester bases by conducting a quick light test. Hold the reel up to a light source: if light "pipes" through, the base is most likely acetate. Reel size can vary, measuring from 2 or 3 inches to 10.5 inches in diameter (14-inch diameters are also possible), with 5, 7, and 10.5 inches being the most common sizes found in archives. The tape width is approximately 2".

- Composition

- Polyester or acetate magnetic tape on a hub or reel

- Deterioration

-

Two-inch open reel audio is susceptible to risks associated with age, hardware, and equipment obsolescence. Like other types of magnetic media, it is prone to risks such as mold, binder deterioration, physical damage, signal drop-outs, and, in the case of acetate-based tapes, base deterioration.

Tapes should be wound tightly and evenly. An uneven tape pack can allow dirt to come in contact with and abrade the tape's surface and edges. Unevenly wound tapes can cause the tape to warp and lose its shape, which will affect playback sound quality.

Tapes are also prone to blocking or pinning, which occurs when layers of tape adhere to adjacent layers. Blocking involves large sections of tape adhered together, while pinning involves small sections. Both blocking and pinning can result in loss of information by damaging the tape layers or by preventing playback. Other issues for many polyester-based tapes are print-through, sticky shed syndrome (binder hydrolysis), and soft binder syndrome. Vinegar syndrome is a concern for many acetate-based tapes.

- Risk Level

- Since magnetic media is a dying medium with a limited lifespan, these tapes should be reformatted based on the content value.

- Playback

- Reel-to-reel audio playback equipment and media are becoming scarce, although there are a few manufacturers that are still filling the needs of professional audio studios. In order to play back a tape properly, you must know the tape track configuration and recording speed. In addition to the proper playback head configuration, playback equipment must have a tape transport able to support the tape's full width in order to read all the tracks encoded on it. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- Open reel audiotape was developed in Germany during the mid-1930s. After World War II, it began to gain worldwide popularity and was further developed in the US by Ampex and EMI. Open reel formats with larger tape widths (½" and above) and recorded at faster speeds (7½ ips and above) are most commonly found in broadcasting and high-quality production environments. Although introduced in the late 1950s, two-inch open reel audiotape did not come into widespread use until the 1960s. 16-track was the solitary configuration up until the early 1970s when 24-track recordings appeared. The 2-inch open reel audiotape was used in professional multitrack recording applications.

- Storage Environment

-

While some base variation for this format is possible, polyester is by far the most common, and guidelines are given assuming a polyester base. If nitrate or acetate base is suspected, colder storage is necessary. Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

The container should support the reel by the hub in order to both preserve the tape pack and prevent distortion of the tape. Use unslotted reels if possible. Acid-free archival hold-down tape should also be used to secure loose ends of the open reel tape.

Whenever feasible, replace original cardboard containers as they are typically non-archival (i.e. acidic) and have little or no hub support. An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- Store all magnetic tape vertically on end, inside the case. Stacking any tape format horizontally--or even allowing it to lean for too long--can compromise a tape pack and cause warping. Its container should provide hub support for the reel in order to preserve the pack and prevent distortions. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Never touch the surface of a magnetic tape recording. Handle by the hub instead. Do not pull on the tape or squeeze the reel flanges. This places stress on the tape, potentially causing distortion and damage. Never leave media in a playback machine; always return to storage enclosure when not in use.

1" Open Reel

- Synonyms

-

- Multitrack recording

- 8-track tape

- 16-track tape (less common as 1")

- Dates

- Early 1950s – 1980s

- Common Size(s)

- Tape width: 1"

- Reel diameter: 3"; 5"; 7"; 10.5"; 14", uncommon

- Description

-

One-inch open reel audio is a magnetic tape-based recorded sound format. The tape is composed of magnetic particles, binder, and a base of either acetate or polyester. Acetate bases can be differentiated from polyester bases by conducting a quick light test. Hold the reel up to a light source—if light "pipes" through, the base is most likely acetate.

While tape width is constant at approximately 1 inch, reel size can vary, measuring from 2 or 3 inches to 10.5 inches in diameter. More rarely, 14 inch diameters are also possible. 5", 7", and 10.5" reels are the most common sizes found in archives. Open reel tapes over ¼" were typically used in studio production (i.e. multitrack recording). 1" audiotape, for instance, might contain 8 tracks or as many as 16 audio tracks. Audio recordings on 1" open reel audiotape are often mistaken for videotape.

- Composition

- Polyester or acetate magnetic tape on a hub or reel

- Deterioration

-

One-inch open reel audio is susceptible to risks associated with age, hardware, and equipment obsolescence. Like other types of magnetic media, it is prone to risks such as mold, binder deterioration, physical damage, signal drop-outs, and, in the case of acetate-based tapes, base deterioration.

Tapes should be wound tightly and evenly. An uneven tape pack can allow dirt to come in contact with and abrade the tape's surface and edges. Unevenly wound tapes can cause the tape to warp and lose its shape, which will affect playback sound quality.

Tapes are also prone to blocking or pinning, which occurs when layers of tape adhere to adjacent layers. Blocking involves large sections of tape adhered together, while pinning involves small sections. Both blocking and pinning can result in loss of information by damaging the tape layers or by preventing playback. Other issues for many polyester-based tapes are print-through, sticky shed syndrome (binder hydrolysis), and soft binder syndrome. Vinegar syndrome is a concern for many acetate-based tapes.

- Risk Level

- Since magnetic media is a dying medium with a limited lifespan, these tapes should be reformatted depending on the value of the content.

- Playback

- Reel-to-reel audio playback equipment and media are becoming scarce, although there are a few manufacturers that are still filling the needs of professional audio studios. In order to play back a tape properly, you must know the tape track configuration and recording speed. In addition to the proper playback head configuration, playback equipment must have a tape transport able to support the tape's full width in order to read all the tracks encoded on it. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- Open reel audiotape was developed in Germany during the mid-1930s. After World War II, it began to gain worldwide popularity and was further developed in the US by Ampex and EMI. Open reel formats with larger tape widths (½" and above) and recorded at faster speeds (7½ ips and above) are most commonly found in professional broadcasting and recording environments. Although developed in the early 1950s, one-inch open reel audiotape did not come into widespread use until the early 1960s.

- Storage Environment

-

While some base variation for this format is possible, polyester is by far the most common, and guidelines are given assuming a polyester base. If nitrate or acetate base is suspected, colder storage is necessary. Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

The container should support the reel by the hub in order to both preserve the tape pack and prevent distortion of the tape. Use unslotted reels if possible. Acid-free archival hold-down tape should also be used to secure loose ends of the open reel tape.

Whenever feasible, replace original cardboard containers as they are typically non-archival (i.e. acidic) and have little or no hub support. An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- Store all magnetic tape vertically on end, inside its case. Stacking any tape format horizontally--or even allowing it to lean for too long--can compromise a tape pack and cause warping. Its container should provide hub support for the reel in order to preserve the pack and prevent distortion. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Never touch the surface of a magnetic tape recording. Handle by the hub instead. Do not pull on the tape or squeeze the reel flanges. This places stress on the tape, potentially causing distortion and damage. Never leave media in a playback machine; always return to storage enclosure when not in use.

½" Open Reel

- Dates

- 1950s - 1980s

- Common Size(s)

- Tape width: ½"

- Reel diameter: 3"; 5"; 7"; 10.5"

- Description

-

Half-inch open reel audio is a magnetic tape-based recorded sound format. The tape is composed of magnetic particles, binder, and a base of either acetate or polyester, with the latter being more common among half-inch tapes. Acetate bases can be differentiated from polyester bases by conducting a quick light test. Hold the reel up to a light source—if light "pipes" through, the base is most likely acetate.

Reel size can vary, measuring from 2 or 3 inches to 10.5 inches in diameter (14-inch diameters are also possible), with 5, 7, and 10.5 inches being the most common sizes found in archives. The tape width is approximately ½". Open reel tapes over ¼" were typically used in studio production (i.e. multitrack recording). A half-inch audio tape may be either 2-, 4-, 8-, or 16-track.

- Composition

- Polyester or acetate magnetic tape on a hub or reel

- Deterioration

-

Half-inch open reel audio is susceptible to risks associated with age, hardware, and equipment obsolescence. Like other types of magnetic media, it is prone to risks such as mold, binder deterioration, physical damage, signal drop-outs, and, in the case of acetate-based tapes, base deterioration.

Tapes should be wound tightly and evenly. An uneven tape pack can allow dirt to come in contact with and abrade the tape's surface and edges. Unevenly wound tapes can cause the tape to warp and lose its shape, which will affect playback sound quality.

Tapes are also prone to blocking or pinning, which occurs when layers of tape adhere to adjacent layers. Blocking involves large sections of tape adhered together, while pinning involves small sections. Both blocking and pinning can result in loss of information by damaging the tape layers or by preventing playback. Other issues for many polyester-based tapes are print-through, sticky shed syndrome (binder hydrolysis), and soft binder syndrome. Vinegar syndrome is a concern for many acetate-based tapes.

- Risk Level

- Since magnetic media is a dying medium with a limited lifespan, these tapes should be reformatted based on the content value.

- Playback

- Reel-to-reel audio playback equipment and media are becoming scarce, although there are a few manufacturers that are still filling the needs of professional audio studios. In order to play back a tape properly, you must know the tape track configuration and recording speed. In addition to the proper playback head configuration, playback equipment must have a tape transport able to support the tape's full width in order to read all the tracks encoded on it. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- Open reel audiotape was developed in Germany during the mid-1930s. After World War II, it began to gain worldwide popularity and was further developed in the US by Ampex and EMI. Open reel formats with larger tape widths (½" and above) and recorded at faster speeds (7½ ips and above) are most commonly found in professional broadcasting and recording environments.

- Storage Environment

-

While some base variation for this format is possible, polyester is by far the most common, and guidelines are given assuming a polyester base. If nitrate or acetate base is suspected, colder storage is necessary. Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

The container should support the reel by the hub in order to both preserve the tape pack and prevent distortion of the tape. Use unslotted reels if possible. Acid-free archival hold-down tape should also be used to secure loose ends of the open reel tape.

Whenever feasible, replace original cardboard containers as they are typically non-archival (i.e. acidic) and have little or no hub support. An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- Store all magnetic tape vertically on end, inside its case. Stacking any tape format horizontally--or even allowing it to lean for too long--can compromise a tape pack and cause warping. Its container should provide hub support for the reel in order to preserve the pack and prevent distortion. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Never touch the surface of a magnetic tape recording. Handle by the hub instead. Do not pull on the tape or squeeze the reel flanges. This places stress on the tape, potentially causing distortion and damage. Never leave media in a playback machine; always return to storage enclosure when not in use.

Continuous Loop Cartridge (Cart)

- Synonyms

-

- NAB cartridge

- 4-track cartridge

- Fidelipac

- Stereo-Pak

- Dates

- 1959 – late 1990s; popular use, 1960s - 1970s

- Common Size(s)

- Tape width: ¼" (6.4mm)

- Cassette: 133mm × 101mm × 23mm; smaller to larger sizes, less common

- Description

- Continuous loop cartridge (cart) is a magnetic tape-based recorded sound format, and it is the 4-track precursor to the 8-track cartridge. The tape is composed of magnetic particles or pigment, binder, and a base. Carts are composed of ¼ inch plastic oxide-coated recording tape wound around a single internal reel and housed in a plastic enclosure. Although carts appear similar to an 8-track, they are distinctly different and are identifiable by a fairly large hole in the lower left backside of the cartridge. Cartridge dimensions are generally 133mm × 101mm × 23mm (NAB A type) but can be found in both smaller and larger sizes (NAB type B and C) depending upon end use and tape length.

- Composition

- Polyester magnetic tape enclosed in a plastic cartridge

- Deterioration

- Magnetic tape is susceptible to physical, biological, and chemical risks like stretching, breaking, drop-outs, mold, and binder deterioration. Additionally, carts are subject to binding and tension problems due to binder lubrication and wind issues.

- Risk Level

- Continuous loop cartridges are especially susceptible to risks associated with age, hardware, and equipment obsolescence. Since carts are often found in broadcast and other working environments, they most likely have been subject to heavy use. Frequent playback wears down the media and degrades the sound quality over time. This format is especially vulnerable, and it should be prioritized for reformatting based on an assessment of its content value.

- Playback

- As carts have been largely replaced by digital technology, the media and its related playback equipment are largely obsolete. The oldest carts, the Audiovendor, were playable on an open reel machine. Subsequent cartridges required proprietary playback equipment until 1964, with the implementation of the National Association of Broadcasters (NAB) audio cartridge standard. Although most carts resemble a commercial 8-track cartridge, they cannot be played back on an 8-track machine. Most carts have tape configurations of mono or two-track stereo; both configurations hold a third cueing track. NAB carts have a typical playback speed of 7.5 inches per second (ips), although playback speed can range from 3.75 ips to 15 ips. Due to the single reel design, carts cannot be rewound. Fast-forward is possible, however, if the playback machine has the functionality to do so. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- Continuous loop cartridges for automatic playback were commercially introduced in 1959. They were used primarily for broadcasting and home/car entertainment until the late 1990s, when MiniDisc and other more sophisticated automated broadcast tools became available. Some major tape manufacturers include Mackenzie Program Repeater, Fidelipac, and Telex "Cart".

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

Inert plastic containers are ideal. If housed in a plastic container and you are unsure if it is acceptable, check the condition of the container. The container is acceptable if it is protecting the media from dust, pests, and other contaminants; is not shedding or introducing any contaminants through its own degradation; and, is clean and free of mold or excessive dirt. Anything other than a hard plastic (e.g. a cardboard slipcover) container means that it is not sufficiently protected and that it should be rehoused in a clean, inert plastic container.

An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- The best orientation for a cassette is vertical on its end. Cassettes and cartridges, generally speaking, like to be stored upright on shelves like books. Piling tapes one upon the other tends to stress the cassettes at bottom; this can, over time, cause the plastic housing to warp and even crack. Allowing cassettes to lean for too long in a suboptimal environment can also lead to distortion. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Engage the record protection mechanism if it has not already been done. Do not attempt to open a tape cassette or cartridge; this is likely to cause greater damage unless you know what you are doing. Furthermore, never touch the magnetic tape surface. Keep magnetic media away from stray electromagnetic fields; avoid devices with a motor or transformer, all of which generate an alternating magnetic field. Never leave media in a playback machine; always return to storage enclosure when not in use. For more information about protection mechanisms, see Playback.

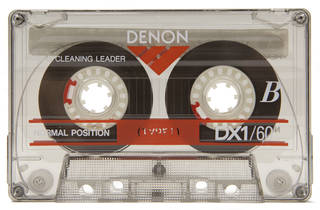

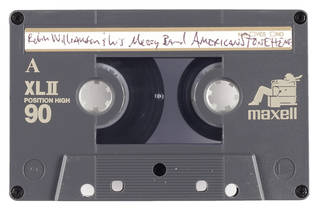

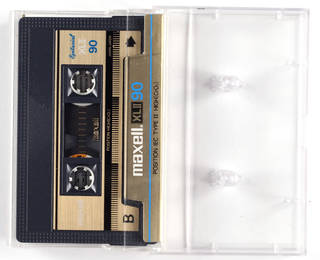

Compact Cassette

- Synonyms

-

- Audiocassette

- Cassette tape

- Dates

- 1963 – present; popular use, 1970s – 1990s

- Common Size(s)

- Tape width: approximately ⅛" (3.81mm)

- Cassette: 4" × 2½" × ½"

- Description

-

Compact cassette is a magnetic tape-based recorded sound format. The tape is composed of magnetic particles or pigment, binder, and a polyester base. Cassettes are composed of ⅛ inch plastic pigment-coated recording tape wound around two internal reels and housed in a plastic enclosure. Ferric oxide is the most common pigment; other pigments include chromium dioxide, metal particle, and metal evaporated tape. Cassette dimensions are approximately 4" × 2½" × ½".

The track configuration is often four-track stereo, where tracks 1 and 2 compose "Side A" and tracks 3 and 4 compose "Side B." Some home-recording enthusiasts may use a four-track recorder to create multi-track recordings. On these tapes, there are four tracks, all recorded in the same direction.

- Composition

- Polyester magnetic tape enclosed in a plastic cassette

- Deterioration

- Magnetic tape is susceptible to physical, biological, and chemical risks like stretching, breaking, drop-outs, improper wind, mold, binder deterioration, and unintended recording. Compact cassettes with tape lengths of longer than 90 minutes are especially prone to print-through, stretching, and breaking as the tape is thinner than shorter length tapes. Frequent playback wears on the media and degrades the sound quality over time. This medium is especially susceptible to damage from playback as it may jam in the playback deck and be "eaten," which can cause crimping and breaking during playback. Internal cassette elements like pads and rollers are susceptible to damage. Cassette housings can be repaired and replaced in the event of damage.

- Risk Level

- The lifespan of a cassette is dependent upon numerous factors: the quality of the original tape, the type and condition of the machine on which it is played, the amount of care the tapes are given, how often they are played, and how they are packaged. Environmental conditions--especially heat, dust, and humidity--may also affect cassettes. As this format is greatly declining in popularity, media and equipment obsolescence may become a risk; at the present however, both media and equipment are available in the marketplace. Frequent playback wears on the media and degrades the sound quality with each playback. The compact cassette medium is not considered an archival format due to its very limited projected lifespan of 10 to 30 years and due to its various technological issues. This format is vulnerable, and it should be prioritized for reformatting based on an assessment of its content value. Standard analog audio cassettes are not suitable for preservation work under any circumstances.

- Playback

- Most compact cassettes have a playback speed of 1 ⅞ ips; however, some recorders were designed to optionally record and play back at 3 ¾ ips for better fidelity. Noise reduction technologies were developed in order to reduce the noise or tape hiss commonly found on thinner tapes recorded at slow speeds. Noise reduction technologies most commonly found on compact cassettes are Dolby (B, C, and S) and dbx (Type II). If a tape has been recorded using noise reduction, the playback equipment must have corresponding noise reduction capabilities in order to accurately play back the tape content. Unfortunately, it is often very difficult to determine if a tape has been recorded with noise reduction without having documentation indicating so. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- Invented in 1962, the compact cassette was introduced by Philips to the public in 1963. It gained popularity in the mid-1970s and prevailed until the mid-1990s when CDs and other digital formats began to supplant it in the marketplace. The compact cassette is still used to record and distribute music in limited arenas.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

Inert plastic containers are ideal. If housed in a plastic container and you are unsure if it is acceptable, check the condition of the container. The container is acceptable if it is protecting the media from dust, pests, and other contaminants; is not shedding or introducing any contaminants through its own degradation; and, is clean and free of mold or excessive dirt. Anything other than a hard plastic (e.g. a cardboard slipcover) container means that it is not sufficiently protected and that it should be rehoused in a clean, inert plastic container.

An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- The best orientation for a cassette is vertical on its end. Cassettes and cartridges, generally speaking, like to be stored upright on shelves like books. Piling tapes one upon the other tends to stress the cassettes at bottom; this can, over time, cause the plastic housing to warp and even crack. Allowing cassettes to lean for too long in a suboptimal environment can also lead to distortion. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Engage the record protection mechanism if it has not already been done. Do not attempt to open a tape cassette or cartridge; this is likely to cause greater damage unless you know what you are doing. Furthermore, never touch the magnetic tape surface. Keep magnetic media away from stray electromagnetic fields; avoid devices with a motor or transformer, all of which generate an alternating magnetic field. Never leave media in a playback machine; always return to storage enclosure when not in use. For more information about protection mechanisms, see Playback.

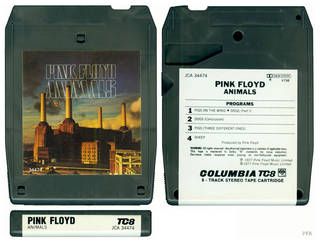

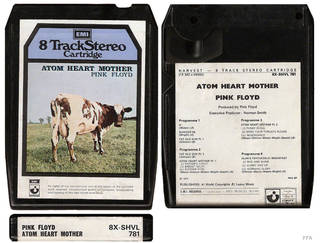

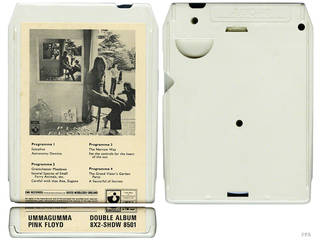

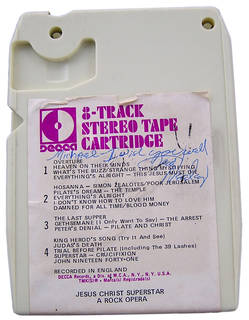

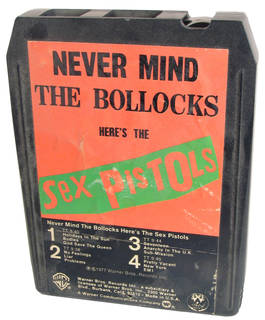

8-Track

- Synonyms

-

- Stereo 8

- 8-track tape/cartridge

- Dates

- 1964 – early 1980s

- Common Size(s)

- Tape width: ¼"

- Cassette: 5¼" × 4" × ⅘"

- Description

- The 8-track cartridge (or Stereo 8) is a magnetic tape-based recorded sound format that was used exclusively for commercially releases. As a result, its content is likely not unique. The tape is composed of magnetic particles or pigment, binder, and a polyester base. Ferric oxide is the most common pigment; other pigments include chromium dioxide, metal particle, and metal evaporated tape. Cartridge dimensions are generally 5¼" × 4" × ⅘" with a tape width of ¼".

- Composition

- Polyester magnetic tape enclosed in a plastic cartridge

- Deterioration

- As with other magnetic media, 8-tracks are susceptible to physical, biological, and chemical risks like stretching, breaking, drop-outs, improper wind, mold, and binder deterioration. The format is also especially susceptible to tape binding due to lubrication loss and jamming in the playback machine.

- Risk Level

- 8-track media and playback equipment are long obsolete. Most recording companies discontinued the release of 8-track media by the early 1980s. As compact cassettes became more popular, the manufacture of playback equipment began to decline in the mid to late 1970s.

- Playback

- 8-track tapes require format-specific equipment for playback. 8-tracks are recorded at a speed of 3.75 ips. The audio is recorded and played back in two-channel stereo with a tape track configuration of eight tracks, each in its own channel going in the same direction, making 4 sides. Since the tracks are so thin and close together and because the playback heads move between the pairs of tracks, the heads often become misaligned. When this misalignment occurs, echoes of adjacent tracks may be heard during playback. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- The Stereo-8 cartridge, more commonly known as the 8-track tape or 8-track, was developed by Bill Lear in 1964. It evolved from the Muntz 4-track and Fidelipac cartridges. It gained its earliest popularity in the mid-1960s with RCA/Victor releasing commercial music on the format and Ford installing optional 8-track players on some of its automobiles. 8-tracks were used mostly for commercial releases. It was a popular format from the mid-1960s through the early 1980s.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

Inert plastic containers are ideal. If housed in a plastic container and you are unsure if it is acceptable, check the condition of the container. The container is acceptable if it is protecting the media from dust, pests, and other contaminants; is not shedding or introducing any contaminants through its own degradation; and, is clean and free of mold or excessive dirt. Anything other than a hard plastic (e.g. a cardboard slipcover) container means that it is not sufficiently protected and that it should be rehoused in a clean, inert plastic container.

An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- The best orientation for a cassette is vertical on its end. Cassettes and cartridges, generally speaking, like to be stored upright on shelves like books. Piling tapes one upon the other tends to stress the cassettes at bottom; this can, over time, cause the plastic housing to warp and even crack. Allowing cassettes to lean for too long in a suboptimal environment can also lead to distortion. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Engage the record protection mechanism if it has not already been done. Do not attempt to open a tape cassette or cartridge; this is likely to cause greater damage unless you know what you are doing. Furthermore, never touch the magnetic tape surface. Keep magnetic media away from stray electromagnetic fields; avoid devices with a motor or transformer, all of which generate an alternating magnetic field. Never leave media in a playback machine; always return to storage enclosure when not in use. For more information about protection mechanisms, see Playback.

Microcassette

- Dates

- 1969 – present; limited use after 1990s

- Common Size(s)

- Tape width: approximately ⅛"

- Cassette: 1 ⅞" × 1 ¼"

- Description

- Microcassette is a magnetic tape-based recorded sound format. The tape is composed of magnetic particles or pigment, binder, and a polyester base. Ferric oxide is the most common pigment; other pigments include chromium dioxide, metal particle, and metal evaporated tape. Cassette dimensions are approximately 1 ⅞" × 1 ¼" with a tape width of approximately ⅛".

- Composition

- Polyester magnetic tape enclosed in a plastic cassette

- Deterioration

- Since the tape is extremely thin, microcassettes are especially prone to breakage and stretching. As with other magnetic media, microcassettes are susceptible to physical, biological, and chemical risks like stretching, breaking, drop-outs, improper wind, mold, binder deterioration, and unintended recording. Frequent playback wears on the media and degrades the sound quality with each playback over time. This medium is especially susceptible to damage from playback as it may jam in the playback deck and be "eaten," which can cause crimping and breaking during playback.

- Risk Level

- The lifespan of a cassette is dependent upon numerous factors: the quality of the original tape, the type and condition of the machine on which it is played, the amount of care the tapes are given, how often they are played, and how they are packaged. The environmental conditions--especially heat, dust, and humidity--may also affect cassettes. Due to the relative fragility of the media, microcassettes have a projected lifespan of 2-10 years. This format is vulnerable, and it should be prioritized for reformatting based on an assessment of its content value.

- Playback

- As this format is greatly declining in popularity, media and equipment obsolescence has become a risk; at present however, both media and equipment are available in the marketplace. While microcassette recorders often recorded at 15/16 ips, most recorders were able to record at variable speeds. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- The microcassette was introduced to the consumer market in 1969 by Olympus. It offered recording times comparable to standard audio cassettes but in a compact form. It is used primarily for voice recording through microcassette recorders and telephone answering machines. This format may be found in research files and oral history collections.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

Inert plastic containers are ideal. If housed in a plastic container and you are unsure if it is acceptable, check the condition of the container. The container is acceptable if it is protecting the media from dust, pests, and other contaminants; is not shedding or introducing any contaminants through its own degradation; and, is clean and free of mold or excessive dirt. Anything other than a hard plastic (e.g. a cardboard slipcover) container means that it is not sufficiently protected and that it should be rehoused in a clean, inert plastic container.

An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- The best orientation for a cassette is vertical on its end. Cassettes and cartridges, generally speaking, like to be stored upright on shelves like books. Piling tapes one upon the other tends to stress the cassettes at bottom; this can, over time, cause the plastic housing to warp and even crack. Allowing cassettes to lean for too long in a suboptimal environment can also lead to distortion. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Engage the record protection mechanism if it has not already been done. Do not attempt to open a tape cassette or cartridge; this is likely to cause greater damage unless you know what you are doing. Furthermore, never touch the magnetic tape surface. Keep magnetic media away from stray electromagnetic fields; avoid devices with a motor or transformer, all of which generate an alternating magnetic field. Never leave media in a playback machine; always return to storage enclosure when not in use. For more information about protection mechanisms, see Playback.

Digital Audio Tape (DAT)

- Synonym

-

- DAT

- Dates

- 1987 – mid 2000s

- Common Size(s)

- Tape width: 4mm

- Cassette: 73mm × 54mm × 10.5mm

- Description

- Digital Audio Tape (DAT) is a digital magnetic tape-based recorded sound format. The tape is composed of magnetic particles or pigment, binder, and a polyester base. Ferric oxide is the most common pigment; others include chromium dioxide, metal particle, and metal evaporated tape. The dimensions of the shell are 73mm × 54mm × 10.5mm with a tape width of 4mm.

- Composition

- Polyester magnetic tape enclosed in a plastic cassette

- Deterioration

- The biggest risk to DAT is format and playback equipment obsolescence. The lifespan of the cassette is dependent upon numerous factors: the quality of the original tape, the type and condition of the machine on which it is played, the amount of care the tapes are given, how often they are played, and how they are packaged. Environmental conditions--especially heat, dust, and humidity--may also affect cassettes. DAT has known playback problems that are typically related to mechanical alignment. DAT is not an archival format. These tapes should be given reformatting priority based on content value.

- Risk Level

- DAT has known playback problems that are typically related to mechanical alignment.

- Playback

- DATs must be played back on format-specific equipment. Since DAT playback equipment is no longer in production, it may be difficult to playback or provide access to the format. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- Digital Audio Tape, or DAT, was developed by the Sony Corporation and introduced in 1987. It was once the preferred method for live compact recording and studio backup. However, the copyright amendment of the Audio Home Recording Act of 1992, which levied a royalty on DAT recorders and media, along with the growing availability and affordability of computer hard drive storage space contributed to making DAT obsolete by the mid-2000s.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

Inert plastic containers are ideal. If housed in a plastic container and you are unsure if it is acceptable, check the condition of the container. The container is acceptable if it is protecting the media from dust, pests, and other contaminants; is not shedding or introducing any contaminants through its own degradation; and, is clean and free of mold or excessive dirt. Anything other than a hard plastic (e.g. a cardboard slipcover) container means that it is not sufficiently protected and that it should be rehoused in a clean, inert plastic container.

An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- The best orientation for a cassette is vertical on its end. Cassettes and cartridges, generally speaking, like to be stored upright on shelves like books. Piling tapes one upon the other tends to stress the cassettes at bottom; this can, over time, cause the plastic housing to warp and even crack. Allowing cassettes to lean for too long in a suboptimal environment can also lead to distortion. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Engage the record protection mechanism if it has not already been done. Do not attempt to open a tape cassette or cartridge; this is likely to cause greater damage unless you know what you are doing. Furthermore, never touch the magnetic tape surface. Keep magnetic media away from stray electromagnetic fields; avoid devices with a motor or transformer, all of which generate an alternating magnetic field. Never leave media in a playback machine; always return to storage enclosure when not in use. For more information about protection mechanisms, see Playback.

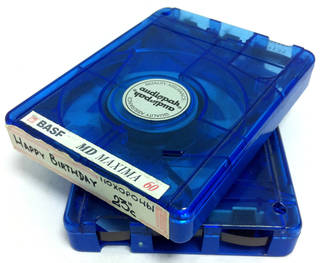

Digital Compact Cassette (DCC)

- Synonyms

-

- DCC

- Dates

- 1992 – late 1990s

- Common Size(s)

- Tape width: ⅛"

- Cassette: 4" × 2½" × ½"

- Description

- Digital Compact Cassette (DCC) is a magnetic tape-based moving image format. The tape is composed of magnetic particles (chromium dioxide- or cobalt- doped ferric-oxide), a binder, and a polyester base. DCC uses PASC (Precision Adaptive Sub-band Coding) compression in order to store the amount of information required for CD-quality sound on an audiotape. The cassette cartridge and tape width is the same as an analog compact cassette (approximately 4" × 2½" × ½" with a ⅛" tape). The cassettes look similar to analog audio cassettes except they only have access holes for the transport hubs on one side. Also, the tape path is shielded by a metal slider similar to those found on a 3.5 inch floppy disc.

- Composition

- Polyester magnetic tape enclosed in a plastic cassette

- Deterioration

- The biggest risk to DCC is format and playback equipment obsolescence. The lifespan of the cassette is dependent upon numerous factors: the quality of the original tape, the type and condition of the machine on which it is played, the amount of care the tapes are given, how often they are played, and how they are packaged. Environmental conditions--especially heat, dust, and humidity--may also affect cassettes.

- Risk Level

- DCC and its associated playback equipment are long obsolete. These tapes should be given reformatting priority based on content value.

- Playback

- DCCs must be played back on format-specific equipment. DCC playback machines were backward-compatible; they supported playback for analog cassettes as well as DCC. See Magnetic Audio Playback for more information about tape speed and track configurations.

- Background

- Digital Compact Cassettes (DCC) were introduced in 1992. A fairly popular format in Europe, DCC was meant to supplant the analog audio tape and to compete with MiniDisc and Digital Audio Tapes (DAT). Once it lost the "format war" to MiniDisc, Philips discontinued manufacturing DCC tapes and playback equipment in 1996.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Temp. 40–54°F (4.5–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Acid-free enclosures are strongly advised. Each item should have its own enclosure to protect it from dust, handling damage, and changes in environmental conditions. All storage materials should pass the Photographic Activity Test (PAT) as specified in ISO Standard 18916:2007 and must be chemically and physically stable.

- Plastic: Polyethylene, polypropylene, or polyester (a.k.a. Mylar D or Melinex 516). No PVC or acetate.

- Paper/Paperboard: Neutral pH, lignin-free, buffered materials recommended.

Inert plastic containers are ideal. If housed in a plastic container and you are unsure if it is acceptable, check the condition of the container. The container is acceptable if it is protecting the media from dust, pests, and other contaminants; is not shedding or introducing any contaminants through its own degradation; and, is clean and free of mold or excessive dirt. Anything other than a hard plastic (e.g. a cardboard slipcover) container means that it is not sufficiently protected and that it should be rehoused in a clean, inert plastic container.

An enclosure must be truly clean to protect the fragile tape surface. Dust and dirt abrasions can affect sound quality and even render the tape unplayable. Moldy, damaged, and dirty containers must be replaced.

- Storage Orientation

- The best orientation for a cassette is vertical on its end. Cassettes and cartridges, generally speaking, like to be stored upright on shelves like books. Piling tapes one upon the other tends to stress the cassettes at bottom; this can, over time, cause the plastic housing to warp and even crack. Allowing cassettes to lean for too long in a suboptimal environment can also lead to distortion. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Engage the record protection mechanism if it has not already been done. Do not attempt to open a tape cassette or cartridge; this is likely to cause greater damage unless you know what you are doing. Furthermore, never touch the magnetic tape surface. Keep magnetic media away from stray electromagnetic fields; avoid devices with a motor or transformer, all of which generate an alternating magnetic field. Never leave media in a playback machine; always return to storage enclosure when not in use. For more information about protection mechanisms, see Playback.

Magnetic Audio Playback

Tape Speed

All tapes are recorded at a particular speed, which is measured in inches per second (ips), and must be played back at that speed for optimum audio quality. Generally, higher-speed recordings have better sound quality. Lower-speed tapes tend to have decreased high-frequency, which increases the amount of noise or tape hiss. More recently developed high-speed cassettes, however, employ noise-reduction technology, such as DBX or Dolby, to reduce tape hiss. The most common playback/record speeds are: 1⅞ ips, 3¾ ips, 7½ ips, 15 ips, and 30 ips.

Tape Track Configuration

In addition to format configurations, tapes can follow a range of different track configurations. It is often difficult to discern the tape track configuration of non-commercial and/or master tapes unless this information has been documented. Track configuration can also be determined by using a magnetic viewer like the Arnold B-1022, which makes the signal recorded on the tape visible. It is essential that the playback head is the same configuration as the track to optimize playback; recording information is otherwise lost or represented incorrectly. Below is a list of the most common tape track configurations as applied most commonly to ¼" tape:

- Full track (monaural): Has one track and one channel; is typically found on ¼" reel-to-reel tape but can pertain to any width tape.

- Half track (also known as two track monaural): two tracks are recorded in opposite directions, with one channel each; is found on ¼" reel-to-reel and monaural cassettes.

- Twin track (also known as "two-track" or "two-track stereo"): Two tracks are found going in the same direction, with each track as a channel; typically found on ¼" reel-to-reel, but can also be used as a half-track mono.

- Quarter track (also known as four-track stereo): Four tracks are found in alternating directions: the 1st and 3rd tracks comprise "SIDE A" and the 2nd and 4th tracks comprise "SIDE B." Tape stock is ¼" wide. Note: channel 1 = side A left; channel 2 = side B left; channel 3 = side A right; channel 4 = side B right.

- Four track (also known as four-track quad): There are four tracks, each going in the same direction and each comprising its own channel. Can be found in ¼" and ½" reel-to-reel. These should be left smoothly wound "tails out" (backwards), according to professional applications and environments.

- Stereo cassette (Phillips, aka "standard format" or "compact cassette"): There are four tracks, with the 1st and 2nd tracks as "SIDE A" and the 3rd and 4th tracks as "SIDE B." Tape stock is ⅛" wide.

- 8-track stereo cartridge: There are eight tracks, each in its own channel and going in the same direction, making 4 sides. Tape stock is ¼" wide. Sixteen track is found on 1" and 2" reel-to-reel. Twenty-four track is found on 2" reel-to-reel.

Audiotape Base Materials

Paper

- Dates

- 1928 - 1950s

- Description

- A rare base material, paper was patented as a medium for recorded sound in 1928 by Fritz Pfleumer but was not available commercially until 1935. It was most commonly used as a base layer in North America from the mid-1940s to the early 1950s. This paper itself will be dull brown and faintly blotchy. As it is inherently old (perhaps 60+ years), paper-based magnetic audiotape can be very fragile. It should be duplicated or digitized whenever possible. Considering its age and the obscurity of paper tape, paper ranks slightly lower than acetate in terms of reformatting priority.

Acetate

- Synonym

-

- Cellulose acetate

- Dates

- 1934 – c. 1970

- Description

- Acetate (cellulose acetate) was the earliest standard of magnetic audiotape recording. It was developed in 1934 for use with AEG/BASF's new Magnetophon. Acetate audiotape suffered a temporary decline during World War II and then began a slow, final phase-out after the emergence of polyester in the 1950s. Manufacture of acetate-based audiotape did, however, continue through the 1960s. Like acetate film, these tapes can suffer from acetate decay, or "vinegar syndrome," as well as from shrinkage and brittleness. Unlike acetate film, acetate-based magnetic tapes cannot be frozen without causing damage to the information layer of the tape; and, acetate decay therefore cannot be halted. This, in addition to acetate's tensile weakness, is why the PSAP considers acetate-based tapes to be of the highest priority for reformatting and preservation.

- Identification

- You can identify acetate tape, particularly those produced post-World War II, by holding it in front of a light source. If the tape pack appears to "glow" or pipe light, it is most likely acetate. Note: the opposite is true for an acetate film pack.

PVC

- Synonyms

-

- Polyvinyl chloride

- Luvitherm

- Dates

- 1942 – 1972

- Description

- PVC is a relatively obscure base layer for magnetic audiotape. Coated PVC audiotape was first developed by BASF in Germany through the independent research of Heinrich Jacque and Rudolf Robl in 1942. It was produced primarily in Germany mainly by BASF from the 1940s to around 1972, its popularity having ebbed in the 1960s as polyester-backed tapes rose in favor. Like polyester, PVC has tensile strength: it will stretch under stress rather than break like acetate. However, PVC-based magnetic tape is unstable due to inherent plasticizer issues. Under repeated use, the binder can shed magnetic iron oxide particles through a process called pinholing. Although PVC-based tape is unreliable, it still ranks between polyester and acetate in terms of preservation priority.

- Identification

- It is difficult to distinguish PVC from polyester tape. A PVC tape pack will appear opaque in front of light like polyester, so the best method of identification is through manufacturer and dating the media. Beyond BASF, other PVC tape manufacturers might include IG Farben (1940s), Agfa (late 1950s), and 3M (Scotch 311, around 1960). Keep in mind that PVC is relatively rare, especially outside of Europe.

-

Non-sticky debris left on playback heads by a PVC-based magnetic tape (BASF LP 35 LH type). Image courtesy of Katrin Abromeit.

Polyester

- Synonyms

-

- PET (polyethylene terephthalate)

- Mylar

- Tenzar

- Dates

- c. 1953 – present

- Description

- Developed during the 1950s, polyester is the most common and stable base for audiotape recordings. Polyester is regarded as the lowest priority for reformatting and preservation. The polyester plasticizer itself is stable. However, the polyurethane binder typically used to carry magnetic particles on PET tapes is prone to both "sticky shed syndrome" (i.e. binder hydrolysis) and the broader condition known as "soft binder syndrome". Degradation of the binder can result in gummy residues on tape heads during playback. It can also degrade cohesive strength to the point that the magnetic coating sheds on playback, resulting in absolute loss of recorded information. This type of deterioration affects many polyester-based magnetic tapes from the 1970s and 1980s.

-

Magnetic tape with sticky shed syndrome. Note the gummy residue left on playback components. This is due to polyurethane binder failure—not the polyester back. Image by Flickr user DRs Kulturarvsprojekt, available under a Creative Commons Attribution ShareAlike license (CC BY-SA 2.0). Courtesy of the Danish Broadcasting Corporation. - Identification

- You can identify polyester by placing the tape pack in front of a light source. If the tape pack appears opaque and you cannot see light through it, it is most likely polyester. Note: The opposite is true for a polyester film pack.

Resources

- Bolnick, D., Johnson, B. (1989, November 15). Audiocassette repair. Library Journal, 114(19), 43-46.

- Hess, R. (2008). Tape degradation factors and challenges in predicting tape life. ARSC (Association for Recorded Sound Collections) Journal, 39(2), 240-274. Retrieved from: http://www.richardhess.com/tape/history/HESS_Tape_Degradation_ARSC_Journal_39-2.pdf

- Paton, C. A. (1998, Spring). Preservation re-recording of audio recordings in archives: Problems, priorities, technologies, and recommendations. American Archivist, 61, 519-546.

- Philips Electronics N.V. (1996). Digital Compact Cassette. Philips Sound & Vision.

- Stauderman, S. (2003, July 24-26). Pictorial guide to sound recording media. Paper presented at the symposium on Sound Savings: Preserving Audio Collections. Association of Research Libraries, Austin, TX. Retrieved from: http://www.arl.org/storage/documents/publications/sound-savings.pdf

- For additional resources, see Audiovisual (General) and Recorded Sound.