Preservation Self-Assessment Program

Film

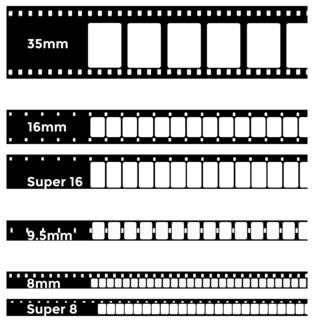

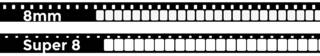

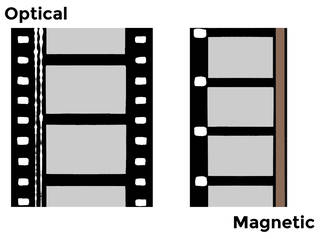

This moving image format type consists of B&W and color photochemical emulsions on translucent plastic backing with sprocket holes running down one or both sides of the film strip. The film strip may contain an optical or magnetic soundtrack. Each of the formats featured are defined by the width (or "gauge") of the film.

- 35mm (1893 – present)

- 9.5mm (1922 – 1950s)

- 16mm (1923 – present)

- 8mm (1932 - present)

- Super 8mm (1965 - present)

Related Notes

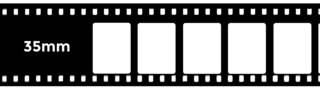

35mm

- Dates

- 1893 – present

- Common Size(s)

- 35mm (1.38") wide

- Description

- This moving image format consists of B&W and color photochemical emulsions on translucent plastic backing with sprocket holes running down one or both sides. The film strip may contain an optical or magnetic soundtrack. If B&W, the plastic support may be nitrate, acetate or polyester. If color, the plastic may be either acetate or polyester. The width of this film format is 35mm, which is a size that is not very commonly found in libraries but can turn up in museums and archives.

- Composition

-

Type Support Binder Image B&W Plastic (Nitrate, Acetate, or Polyester) Gelatin Silver Particles Color Plastic (Acetate or Polyester) Gelatin Yellow, Magenta, and Cyan Dyes - Deterioration

- Motion picture film is prone to the following problems: nitrate breakdown (if cellulose nitrate is the base), acetate breakdown/vinegar syndrome (if cellulose acetate is the base), mold, and physical damage (e.g. torn sprocket holes, damaged splices, scratches, and mag stock breakdown). Cellulose acetate has a characteristic kind of breakdown known as "vinegar syndrome." Polyester is a very stable plastic; films with this base can have very long, viable lives if stored properly.

- Risk Level

- In the case of cellulose nitrate-based films, the preservation risk level is very high. Other film bases should be considered at moderate risk because of motion picture film's impending obsolescence.

- Playback

-

Film is unique compared to other AV media in that the information can be seen with the naked eye: one can see the images printed on the film without an intermediary machine. A means of projection, however, is required in order to view the film as intended. For each film gauge, there is a family of like-gauged equipment and supplies designed to work together. Manufacturers make the film stock with holes, usually along the edges, to advance the film strip through the sprockets of same-gauged cameras and projectors. Stated simply, you must have a projector that corresponds to the film gauge you have in order to play it back.

Film incurs the most physical wear through playback, typically at the beginning and end of the film. Films can become stuck in the projector or misalign with the take-up sprockets, causing sprocket holes to tear and other serious damage. For film in poor condition, projecting a film can pose a significant risk, since projectors can inflict additional damage to films already weakened by shrinkage, tears, or decay. We highly recommend having a skilled technician perform a thorough inspection of the film and playback equipment prior to projecting the film.

- Background

- 35mm film was first developed in 1893 and is still in use today. Films produced before the 1950s may use flammable cellulose nitrate as their plastic base, and they should be treated and stored with great care. Motion picture films produced after the 1950s may use cellulose acetate or polyester as their base.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Acceptable Temp. 0–32°F (-18–0°C) 33–54°F (1–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Container: Film is ideally stored in a vented inert plastic can. Vents allow the film to “breathe” an even air exchange (crucial for acetate). The enclosure may be plastic, non-corrosive metal, or archival quality paperboard. Dirty, rusty, non-vented, or dented metal containers will only heighten the potential for film damage. The container your institution uses will largely depend upon the environment.

If storing film in a room temperature environment, vented containers composed of polypropylene or polyethylene are optimal. If you are storing your film in freezing temperatures, your cans should be sealed and moisture-resistant. In any case, cans should be clean and free from debris, rust, and structural damage. When freezing film, ensure that the the film is properly housed by double-bagging it in zip-sealed freezer bags.

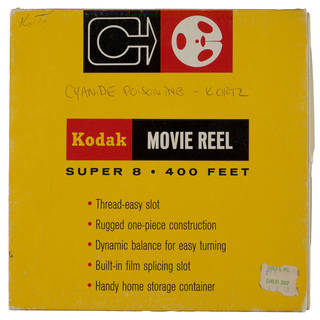

Core: Film should be stored on a core, which is ideally made from inert plastic, rather than on a reel. For 16mm and 35mm, the National Film Preservation Foundation (NFPF) recommends that the core be at least 3 inches wide. A wider core diameter lessens stress on the film as the film will not be wound as tightly. Smaller film gauges may be wound on smaller (less than 3") cores. A core is distinct from a reel. A reel is a metal or plastic hub with extended sides between which the film is wound for projection. Reels—especially metal, dented, or otherwise damaged reels—are NOT appropriate for long-term storage.

- Storage Orientation

-

Film should be stored stacked horizontally. It is best to store film flat and on an inert plastic core because of its considerable weight and the way that it is wound. Doing so will allow the film to maintain an even, rounded shape. Stacking film on reels without a film canister of some kind is not recommended because the reels will, over time, be compressed and can press into the film itself.

Store acetate film separately from other materials in order to mitigate the effects of acetic acid decomposition (e.g. off-gassing). Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

-

Always wear nitrile or cotton gloves when handling film. Cotton gloves may be problematic if the film has many tape splices or fragile edges/sprocket holes. Handle only by the edges. If you touch the film image or soundtrack without gloves, you will leave fingerprints. Assume the film is easily torn, regardless of base material; take care whenever handling it. Never leave media in a playback machine; always return to storage enclosure when not in use.

If you are interested in freezing infrequently accessed materials, refer to The Home Film Preservation Guide (sec. 8) for detailed steps on how prepare your film for long-term freezing.

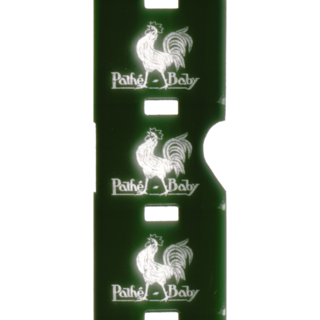

9.5mm

- Synonyms

-

- Notched 9.5mm

- Dates

- 1922 – 1950s

- Common Size(s)

- 9.5mm (0.37") wide

- Description

- This moving image format consists of B&W and color photochemical emulsions on translucent plastic backing (acetate or polyester) with sprocket holes running down the center of the film strip between each image frame. There may be a magnetic soundtrack running down one side of the film strip. The width of this film format is 9.5mm (0.37 inches). This format is rarely found in the United States but is more common in Europe.

- Composition

-

Type Support Binder Image B&W Plastic (Acetate or Polyester) Gelatin Silver Particles Color Plastic (Acetate or Polyester) Gelatin Yellow, Magenta, and Cyan Dyes - Deterioration

- This motion picture film format is prone to the following problems: acetate breakdown/vinegar syndrome (if cellulose acetate is the base), mold, and physical damage (e.g. torn sprocket holes, damaged splices, scratches, and mag stock breakdown).

- Risk Level

- Because of the rarity and obsolescence of this film format, its preservation risk should be considered very high.

- Playback

-

Film is unique compared to other AV media in that the information can be seen with the naked eye; one can see the images printed on the film without an intermediary machine. A means of projection, however, is required in order to view the film as intended. For each film gauge, there is a family of like-gauged equipment and supplies designed to work together. Manufacturers make the film stock with holes, usually along the edges, to advance the film strip through the sprockets of same-gauged cameras and projectors. Stated simply, you must have a projector that corresponds to the film gauge you have in order to play it back.

Film incurs the most physical wear through playback, typically at the beginning and end of the film. Films can become stuck in the projector or misalign with the take-up sprockets, causing sprocket holes to tear and other serious damage. For film in poor condition, projecting a film can pose a significant risk, since projectors will inflict additional damage to films already weakened by shrinkage, tears, or decay. We highly recommend having a skilled technician perform a thorough inspection of the film and playback equipment prior to projecting the film.

- Background

- Pathé introduced this film format in 1922 to go with the new Pathé-Baby camera. By the end of the 1920s, 9.5mm had risen in popularity across the European amateur film market, where it held on until the 1950s, when 8mm film emerged as the commerical victor. 9.5mm film, however, never caught on in the United States. Most projectors were hand-cranked. Sound was introduced in the 1930s. The film format typically has a cellulose acetate plastic base.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Acceptable Temp. 0–32°F (-18–0°C) 33–54°F (1–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Container: Film is ideally stored in a vented inert plastic can. Vents allow the film to “breathe” an even air exchange (crucial for acetate). The enclosure may be plastic, non-corrosive metal, or archival quality paperboard. Dirty, rusty, non-vented, or dented metal containers will only heighten the potential for film damage. The container your institution uses will largely depend upon the environment.

If storing film in a room temperature environment, vented containers composed of polypropylene or polyethylene are optimal. If you are storing your film in freezing temperatures, your cans should be sealed and moisture-resistant. In any case, cans should be clean and free from debris, rust, and structural damage. When freezing film, ensure that the the film is properly housed by double-bagging it in zip-sealed freezer bags.

Core: Film should be stored on a core, which is ideally made from inert plastic, rather than on a reel. For larger film gauges, the National Film Preservation Foundation (NFPF) recommends that the core be at least 3 inches wide. A wider core diameter lessens stress on the film as the film will not be wound as tightly. Smaller film gauges may be wound on smaller (less than 3") cores. A core is distinct from a reel. A reel is a metal or plastic hub with extended sides between which the film is wound for projection. Reels—especially metal, dented, or otherwise damaged reels—are NOT appropriate for long-term storage.

- Storage Orientation

-

Film should be stored stacked horizontally. It is best to store film flat and on an inert plastic core because of its considerable weight and the way that it is wound. Doing so will allow the film to maintain an even, rounded shape. Stacking film on reels without a film canister of some kind is not recommended because the reels will, over time, be compressed and can press into the film itself.

Store acetate film separately from other materials in order to mitigate the effects of acetic acid decomposition (e.g. off-gassing). Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

-

Always wear nitrile or cotton gloves when handling film. Cotton gloves may be problematic if the film has many tape splices or fragile edges/sprocket holes. Handle only by the edges. If you touch the image or soundtrack without gloves, you will leave fingerprints. Assume the film is easily torn, regardless of base material; take care whenever handling it. Never leave media in a playback machine; always return to storage enclosure when not in use.

If you are interested in freezing infrequently accessed materials, refer to The Home Film Preservation Guide (sec. 8) for detailed steps on how prepare your film for long-term freezing.

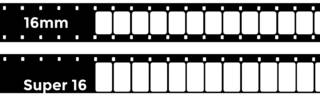

16mm

- Dates

- 1923 – present; use declining after 1970s

- Common Size(s)

- 16mm (0.63") wide

- Description

- This moving image format consists of B&W and color photochemical emulsions on translucent plastic backing (acetate or polyester) with sprocket holes running down one or both sides. The film strip may contain an optical or magnetic soundtrack. The width of this film format is 16mm, which is a format commonly found in libraries, archives, and museums.

- Composition

-

Type Support Binder Image B&W Plastic (Acetate or Polyester) Gelatin Silver Particles Color Plastic (Acetate or Polyester) Gelatin Yellow, Magenta, and Cyan Dyes - Deterioration

- 16mm motion picture film is prone to the following problems: acetate breakdown/vinegar syndrome (if cellulose acetate is the base), mold, and physical damage (e.g. torn sprocket holes, damaged splices, scratches, and mag stock breakdown). Cellulose acetate has a characteristic kind of breakdown known as "vinegar syndrome." Polyester is a very stable plastic; films with this base can have very long, viable lives if stored properly.

- Risk Level

- This film format should be considered at moderate preservation risk because of motion picture film's impending obsolescence.

- Playback

-

Film is unique compared to other AV media in that the information can be seen with the naked eye; one can see the images printed on the film without an intermediary machine. A means of projection, however, is required in order to view the film as intended. For each film gauge, there is a family of like-gauged equipment and supplies designed to work together. Manufacturers make the film stock with holes, usually along the edges, to advance the film strip through the sprockets of same-gauged cameras and projectors. Stated simply, you must have a projector that corresponds to the film gauge you have in order to play it back.

Film incurs the most physical wear through playback, typically at the beginning and end of the film. Films can become stuck in the projector or misalign with the take-up sprockets, causing sprocket holes to tear and other serious damage. For film in poor condition, projecting a film can pose a significant risk, since projectors can inflict additional damage to films already weakened by shrinkage, tears, or decay. We highly recommend having a skilled technician perform a thorough inspection of the film and playback equipment prior to projecting the film.

- Background

- The 16mm film gauge was first developed by Kodak in 1923 as an amateur's affordable alternative to 35mm, and it is still in use today. 16mm film is found with acetate or polyester plastic bases. RCA introduced synchronized sound for 16mm cameras in 1933.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Acceptable Temp. 0–32°F (-18–0°C) 33–54°F (1–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Container: Film is ideally stored in a vented inert plastic can. Vents allow the film to “breathe” an even air exchange (crucial for acetate). The enclosure may be plastic, non-corrosive metal, or archival quality paperboard. Dirty, rusty, non-vented, or dented metal containers will only heighten the potential for film damage. The container your institution uses will largely depend upon the environment.

If storing film in a room temperature environment, vented containers composed of polypropylene or polyethylene are optimal. If you are storing your film in freezing temperatures, your cans should be sealed and moisture-resistant. In any case, cans should be clean and free from debris, rust, and structural damage. When freezing film, ensure that the the film is properly housed by double-bagging it in zip-sealed freezer bags.

Core: Film should be stored on a core, which is ideally made from inert plastic, rather than on a reel. For 16mm and 35mm, the National Film Preservation Foundation (NFPF) recommends that the core be at least 3 inches wide. A wider core diameter lessens stress on the film as the film will not be wound as tightly. Smaller film gauges may be wound on smaller (less than 3") cores. A core is distinct from a reel. A reel is a metal or plastic hub with extended sides between which the film is wound for projection. Reels—especially metal, dented, or otherwise damaged reels—are NOT appropriate for long-term storage.

- Storage Orientation

-

Film should be stored stacked horizontally. It is best to store film flat and on an inert plastic core because of its considerable weight and the way that it is wound. Doing so will allow the film to maintain an even, rounded shape. Stacking film on reels without a film canister of some kind is not recommended because the reels will, over time, be compressed and can press into the film itself.

Store acetate film separately from other materials in order to mitigate the effects of acetic acid decomposition (e.g. off-gassing). Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

-

Always wear nitrile or cotton gloves when handling film. Cotton gloves may be problematic if the film has many tape splices or fragile edges/sprocket holes. Handle only by the edges. If you touch the image or soundtrack without gloves, you will leave fingerprints. Assume the film is easily torn, regardless of base material; take care whenever handling it. Never leave media in a playback machine; always return to storage enclosure when not in use.

If you are interested in freezing infrequently accessed materials, refer to The Home Film Preservation Guide (sec. 8) for detailed steps on how prepare your film for long-term freezing.

8mm

- Synonyms

-

- Regular 8mm

- Dates

- 1932 – present; U.S. production ceased in early 1990s

- Common Size(s)

- 8mm (0.31") wide

- Description

- This moving image format consists of B&W and color photochemical emulsions on translucent plastic (acetate) backing with sprocket holes running down one side. The film strip may also contain a magnetic soundtrack running down one side. The width of this film format is 8mm (0.31 inches). It is a format commonly found in libraries, archives, museums, and especially home movie collections.

- Composition

-

Type Support Binder Image B&W Plastic (Acetate) Gelatin Silver Particles Color Plastic (Acetate) Gelatin Yellow, Magenta, and Cyan Dyes - Deterioration

- Regular 8mm film is prone to the following problems: acetate breakdown/vinegar syndrome (if cellulose acetate is the base), mold, and physical damage (e.g. torn sprocket holes, damaged splices, scratches, and mag stock breakdown). Cellulose acetate has a characteristic kind of breakdown known as "vinegar syndrome."

- Risk Level

- This film format should be considered at moderate preservation risk because of motion picture film's impending obsolescence.

- Playback

-

Film is unique compared to other AV media in that the information can be seen with the naked eye; one can see the images printed on the film without an intermediary machine. A means of projection, however, is required in order to view the film as intended. For each film gauge, there is a family of like-gauged equipment and supplies designed to work together. Manufacturers make the film stock with holes, usually along the edges, to advance the film strip through the sprockets of same-gauged cameras and projectors. Stated simply, you must have a projector that corresponds to the film gauge you have in order to play it back

Film incurs the most physical wear through playback, typically at the beginning and end of the film. Films can become stuck in the projector or misalign with the take-up sprockets, causing sprocket holes to tear and other serious damage. For film in poor condition, projecting a film can pose a significant risk, since projectors will inflict additional damage to films already weakened by shrinkage, tears, or decay. We highly recommend having a skilled technician perform a thorough inspection of the film and playback equipment prior to projecting the film.

- Background

- The 8mm film gauge, often called regular 8mm to distinguish it from Super 8mm, was first developed by Kodak in 1932. North American production of 8mm ceased in the early 1990s, but the use of 8mm film persists in "boutique" numbers. This film format can be distinguished from Super 8mm by its smaller image area and larger sprocket holes. Regular 8mm film is found only with an acetate plastic base.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Acceptable Temp. 0–32°F (-18–0°C) 33–54°F (1–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Container: Film is ideally stored in a vented inert plastic can. Vents allow the film to “breathe” an even air exchange (crucial for acetate). The enclosure may be plastic, non-corrosive metal, or archival quality paperboard. Dirty, rusty, non-vented, or dented metal containers will only heighten the potential for film damage. The container your institution uses will largely depend upon the environment.

If storing film in a room temperature environment, vented containers composed of polypropylene or polyethylene are optimal. If you are storing your film in freezing temperatures, your cans should be sealed and moisture-resistant. In any case, cans should be clean and free from debris, rust, and structural damage. When freezing film, ensure that the the film is properly housed by double-bagging it in zip-sealed freezer bags.

Core: Film should be stored on a core, which is ideally made of inert plastic, rather than on a reel. For larger film gauges, the National Film Preservation Foundation (NFPF) recommends that the core be at least 3 inches wide. A wider core diameter lessens stress on the film as the film will not be wound as tightly. Smaller film gauges may be wound on smaller (less than 3") cores. A core is distinct from a reel. A reel is a metal or plastic hub with extended sides between which the film is wound for projection. Reels—especially metal, dented, or otherwise damaged reels—are NOT appropriate for long-term storage.

- Storage Orientation

-

Film should be stored stacked horizontally. It is best to store film flat and on an inert plastic core because of its considerable weight and the way that it is wound. Doing so will allow the film to maintain an even, rounded shape. Stacking film on reels without a film canister of some kind is not recommended because the reels will, over time, be compressed and can press into the film itself.

Store acetate film separately from other materials in order to mitigate the effects of acetic acid decomposition (e.g. off-gassing). Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

-

Always wear nitrile or cotton gloves when handling film. Cotton gloves may be problematic if the film has many tape splices or fragile edges/sprocket holes. Handle only by the edges. If you touch the image or soundtrack without gloves, you will leave fingerprints. Assume the film is easily torn, regardless of base material; take care whenever handling it. Never leave media in a playback machine; always return to storage enclosure when not in use.

If you are interested in freezing infrequently accessed materials, refer to The Home Film Preservation Guide (sec. 8) for detailed steps on how prepare your film for long-term freezing.

Super 8mm

- Synonyms

-

- Super 8

- Dates

- 1965 – present

- Common Size(s)

- 8mm (0.31") wide

- Description

- This moving image format consists of B&W and color photochemical emulsions on translucent plastic (acetate or polyester) backing with sprocket holes running down one side. The film strip may also contain a magnetic soundtrack running down one side. The width of this film format is 8mm. Super 8 may be in color or black-and-white. It is a format commonly found in libraries, archives, museums, and especially home movie collections.

- Composition

-

Type Support Binder Image B&W Plastic (Acetate or Polyester) Gelatin Silver Particles Color Plastic (Acetate or Polyester) Gelatin Yellow, Magenta, and Cyan Dyes - Deterioration

- Super 8mm films are prone to the following problems: acetate breakdown/"vinegar syndrome" (if cellulose acetate is the base), mold, and physical damage (e.g. torn sprocket holes, damaged splices, scratches, and mag stock breakdown). Polyester is a very stable plastic, and films with this base can have very long, viable lives if stored properly.

- Risk Level

- This film format should be considered at moderate preservation risk because of motion picture film's impending obsolescence.

- Playback

-

Film is unique compared to other AV media in that the information can be seen with the naked eye; one can see the images printed on the film without an intermediary machine. A means of projection, however, is required in order to view the film as intended. For each film gauge, there is a family of like-gauged equipment and supplies designed to work together. Manufacturers make the film stock with holes, usually along the edges, to advance the film strip through the sprockets of same-gauged cameras and projectors. Stated simply, you must have a projector that corresponds to the film gauge you have in order to play it back.

Film incurs the most physical wear through playback, typically at the beginning and end of the film. Films can become stuck in the projector or misalign with the take-up sprockets, causing sprocket holes to tear and other serious damage. For film in poor condition, projecting a film can pose a significant risk, since projectors will inflict additional damage to films already weakened by shrinkage, tears, or decay. We highly recommend having a skilled technician perform a thorough inspection of the film and playback equipment prior to projecting the film.

- Background

- The Super 8mm film gauge was first developed by Kodak in the mid-1960s, and it is still in use today. This film format can be distinguished from regular 8mm film by its larger image area and smaller sprocket holes. Super 8mm film is found with acetate or polyester plastic bases.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Acceptable Temp. 0–32°F (-18–0°C) 33–54°F (1–12°C) RH 30–50% RH - Storage Enclosure(s)

-

Container: Film is ideally stored in a vented inert plastic can. Vents allow the film to “breathe” an even air exchange (crucial for acetate). The enclosure may be plastic, non-corrosive metal, or archival quality paperboard. Dirty, rusty, non-vented, or dented metal containers will only heighten the potential for film damage. The container your institution uses will largely depend upon the environment.

If storing film in a room temperature environment, vented containers composed of polypropylene or polyethylene are optimal. If you are storing your film in freezing temperatures, your cans should be sealed and moisture-resistant. In any case, cans should be clean and free from debris, rust, and structural damage. When freezing film, ensure that the the film is properly housed by double-bagging it in zip-sealed freezer bags.

Core: Film should be stored on a core, which is ideally made of inert plastic, rather than on a reel. For larger film gauges, the National Film Preservation Foundation (NFPF) recommends that the core be at least 3 inches wide. A wider core diameter lessens stress on the film as the film will not be wound as tightly. Smaller film gauges may be wound on smaller (less than 3") cores. A core is distinct from a reel. A reel is a metal or plastic hub with extended sides between which the film is wound for projection. Reels—especially metal, dented, or otherwise damaged reels—are NOT appropriate for long-term storage.

- Storage Orientation

-

Film should be stored stacked horizontally. It is best to store film flat and on an inert plastic core because of its considerable weight and the way that it is wound. Doing so will allow the film to maintain an even, rounded shape. Stacking film on reels without a film canister of some kind is not recommended because the reels will, over time, be compressed and can press into the film itself.

Store acetate film separately from other materials in order to mitigate the effects of acetic acid decomposition (e.g. off-gassing). Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

-

Always wear nitrile or cotton gloves when handling film. Cotton gloves may be problematic if the film has many tape splices or fragile edges/sprocket holes. Handle only by the edges. If you touch the image or soundtrack without gloves, you will leave fingerprints. Assume the film is easily torn, regardless of base material; take care whenever handling it. Never leave media in a playback machine; always return to storage enclosure when not in use.

If you are interested in freezing infrequently accessed materials, refer to The Home Film Preservation Guide (sec. 8) for detailed steps on how prepare your film for long-term freezing.

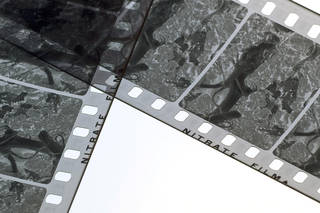

Film Base Materials

Film formats are composed of two layers: the emulsion layer, which supports the photosensitive material, and the thicker transparent plastic base, which supports the emulsion layer. The base is generally composed of one of three types of plastic: nitrate, acetate, or polyester. Bases may be identified based on a few factors. Date can be an important indicator, as can film gauge. Of the three materials, nitrate is the oldest, is the most volatile, and requires the most care in handling. Acetate film was introduced in 1909. Although it was developed to circumvent the danger of nitrate, acetate film is still subject to its own particular kind of decay. Polyester film is the youngest and most stable film base.

Identifying Film Base

To positively identify the film base, you may have to partially unspool the film. Unspooling film, however, is not without risk. If you are unable or unwilling to unspool your film and if you lack the relevant documentation, we recommend you click on "Unsure" when identifying the film base on the PSAP.

When we talk about film base, we are talking about the plastic layer that is the carrier for the emulsion layer (i.e. the image layer) of film.

| Nitrate | Acetate | Polyester |

|---|---|---|

| Found in 35mm gauge, from c. 1889 through the early 1950s. | Most film stock produced after 1950; some produced as early as 1930s. | Produced after 1955; sold under trade names like Chronar (Dupont), ESTAR (Kodak), and Mylar. |

| May have "NITRATE" printed on the edge of the film if manufactured after 1920. | "SAFETY" often printed on the edge of film stock. | Does not tear easily; does not have cement splices. |

| Nitrate film odor is often described as having the smell of dirty socks. | Hold the film reel up to a light source (film pack parallel to your eyes). If light CANNOT be seen piping through the film strands, it is most likely an acetate-base film. | Hold the film reel up to a light source (film pack parallel to your eyes). If light CAN be seen piping through the film strands, it is most likely an polyester-base film. |

Nitrate

Most 35mm film bases prior to the early 1950s are composed of cellulose nitrate. Nitrate is a highly flammable material, with nitrate fires being nearly impossible to extinguish once they've started. It can ignite at relatively low temperatures—ranging from 300°F to 105°F in later stages of decay. In the 1920s, Kodak began labeling nitrate film by printing "NITRATE" on the edge of the film.

- Nitrate film is the highest preservation priority.

- "NITRATE" printed along the edge of the film.

- Nitrate is found most often in 35mm gauge.

- Nitrate odor has been described as the smell of dirty socks.

Acetate

Acetate film in its various chemical forms (ranging from cellulose diacetate in 1909 to cellulose triacetate in the 1940s) was an improvement over nitrate film in that acetate was not nearly as flammable. Consequently, acetate films became to be known as "safety film," and manufacturers identified their film as safety by labeling it as such. The text "SAFETY" is often printed along the edge of early acetate film.

An additional way to identify acetate is to place the film pack parallel to a light source. If light cannot be seen piping through the film strands, it is most likely an acetate-base film. The film will appear opaque and light will not filter through the film pack. Acetate film can be found in a variety of gauges: 35mm, 28mm, 16mm, 9.5mm, regular 8mm, and Super 8mm.

- Acetate film is the second-highest preservation priority.

- Acetate is found in 35mm, 16mm, 8mm, and Super 8 gauges.

- Acetate will often emit an vinegar odor if it is suffering from acetate decay.

- Store acetate film separately from other materials in order to mitigate the effects of acetic acid decomposition (e.g. off-gassing).

- The easiest way to differentiate acetate base film from polyester base film is to hold the film up to the light (see below for an image). If it appears to be fairly opaque, it is acetate (Note: the reverse is true of magnetic audiotape).

Polyester

Polyester is the most recently developed film base. It was developed in the mid-1950s, and it continues to be the standard for film-to-film archival preservation because of its durability. It cannot be easily torn and is chemically stable. You can identify a polyester film base by shining light upwards through and parallel to a horizontally oriented film pack. If the pack appears to "pipe" light (i.e. light can be seen through the film pack), the film is polyester-based.

- Polyester film is the lowest preservation priority.

- The easiest way to differentiate acetate base film from polyester base film is to hold the film up to the light. If light easily passes through the film pack, the film is polyester. If it appears to be fairly opaque, it is acetate. (Note: the reverse is true of magnetic audiotape.)

Sound on Film: Soundtracks

To determine the soundtrack type, partially unspooling the film will likely be necessary. This step, however, is not without risk.

A soundtrack on film is often identified by a continuous stripe running along the length of the film. It looks considerably different than the film picture frames. The strip may be a reddish-brown color (a magnetic, or "mag," soundtrack). It may also look like two strips that contain similar wavy forms (a variable area optical soundtrack), or it may look like a gray strip of varying darkness (a variable density optical soundtrack).

The soundtrack may not be on the film but could be a separate, individual element. For example, some film-makers create a full-coat mag, which is a production or preservation element in which the magnetic oxide recording layer covers one full side of the film surface.

If your film does not have a soundtrack and it is a 35mm or 16mm, you may want to seek out production notes to determine if there are any additional sound elements. Preservationists should watch for commentary, dialog, or music recorded on a separate audiotape reel or cassette that was intended to be played with the film during screening. This is particularly the case with collections of amateur and avant-garde films.

Resources

- National Film Preservation Foundation. (2004). The film preservation guide: The basics for archives, libraries and museums. San Francisco, CA: National Film Preservation Foundation.

- For additional resources, see Audiovisual (General) and Moving Image.