Preservation Self-Assessment Program

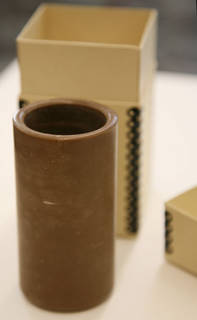

Grooved Cylinder

This audio format type consists of a grooved phonograph cylinder composed of wax or plastic. The sound information is inscribed as grooves along the cylinder exterior and is played back with a needle or stylus. Cylinders were commerically available from the late 1880s up through the late 1920s.

- Wax Cylinder (late 1880s – c. 1915)

- Plastic Cylinder (c. 1900 – c. 1929)

Wax Cylinder

- Synonyms

-

- Brown cylinder

- Edison "Gold-Moulded" cylinder/record

- Dates

- late 1880s – c. 1915

- Common Size(s)

- Variable, but typically about 2¼" (diameter) × 4–4¼" (length)

- Common Color(s)

- Black; brown

- Description

- A wax cylinder is an analog recording sound format that consists of a mechanical grooved cylinder made of soft wax. The earliest wax cylinders are ivory or cream colored, while subsequent wax cylinders are a warm medium brown color. The "standard" cylinder dimensions are typically 2¼" in diameter and 4–4¼" in length, although they vary widely, ranging from 1⅓" diameter × 4" length, 2¼" diameter × 8" length, 3¾" diameter by 6" length, and 5" diameter × 4" length.

- Composition

- Molded wax cylinder that may or may not have a cardboard core. Regardless of composition, most cylinders should be regarded as very fragile and must be cared for as such.

- Deterioration

- All grooved cylinder media is susceptible to warpage, breakage, groove wear, and surface contamination. Surface contamination includes dirt, dust, mold, and other foreign materials—all of which can abrade or damage the grooves and diminish playback sound quality. Wax cylinders are especially prone to issues related to humid storage environments, namely fungal growth. Additionally, materials within the wax cylinder harden with age, causing the wax to become brittle. The surface of wax cylinders is soft and fragile, and they are also prone to surface scratching and groove wear. Brown cylinders are composed of a soft wax that makes them particularly susceptible to groove wear and damage. Black wax cylinders may be assumed harder than brown.

- Risk Level

- Cylinders should be given priority for reformatting because of the age, fragility, obsolenscence, and relative uniqueness of their content.

- Playback

- Cylinders require format-specific machines for playback. Cylinders of different diameters cannot be played on the same machine; and, attempting to do so will damage the cylinder. The earliest wax cylinders are typically 2 to 2.5 minutes in length with 100 grooves per inch. Playback speed is also a consideration, since cylinders have different rotation speeds depending on the manufacturer and technology. Rotation speeds include 120 rpm, 144 rpm, and 160 rpm.

- Background

- Cylinders are the earliest manufactured recorded sound format. They were developed by Thomas Edison in 1877 and remained in commercial production until 1929. Brown wax cylinders were most prevalent until 1902, when more rigid wax formulas debuted. The Edison Gold Moulded cylinder was produced from 1902 to 1912, during the period when plastic cylinders were introduced to--and then took over--the market. Cylinder recording technology was still used from the 1930s until the early 1960s for ethnographic field recording notes and office dictation.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Acceptable Temp. 40–54°F (4.5–12°C) 33–44°F (0.5–6.5°C) RH 30–50% RH - Storage Enclosure(s)

- Archival quality boxes are available specifically for cylinders. These are small, acid-free boxes that often have a cylindrical baffle inside, on which the cylinder is placed to secure it within the box. Cylinders should be stored in containers designed to support them vertically, bearing the weight at the bottom and protecting the surface from any pressure or contact with the container.

- Storage Orientation

- Cylinders should be stored standing on their ends like a drinking glass. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Cylinders should only be handled on the inside and at the top and bottom edges. Never touch the grooves on the cylinder exterior. If you must handle, insert two (or more) fingers into the cylinder interior and then use your other palm to support the bottom edge. Never leave media in a playback machine; always return to storage enclosure when not in use.

Plastic Cylinder

- Synonyms

-

- Celluloid cylinder

- "Indestructible" cylinder/record

- Edison Blue Amberol

- Edison Royal Purple Amberol

- Dates

- c. 1900 – c. 1929

- Common Size(s)

- Variable, but typically about 2¼" (diameter) × 4–4¼" (length)

- Common Color(s)

- Black; blue; purple

- Description

- The plastic cylinder is a mechanical grooved analog recording sound format. The "standard" cylinder dimensions are typically 2¼" in diameter and 4–4¼" in length, although they vary widely, ranging from 1⅓" diameter × 4" length, 2¼" diameter × 8" length, 3¾" diameter by 6" length, and 5" diameter × 4" length.

- Composition

- Pre-recorded molded plastic (cellulose nitrate) cylinders were available starting in the early 1900s. Cylinders composed of celluloid molded around a cardboard or plaster core were available after 1908. Regardless of composition, most cylinders should be regarded as very fragile and must be cared for as such.

- Deterioration

- All grooved cylinder media is susceptible to warpage, breakage, groove wear, and surface contamination. Surface contamination includes dirt, dust, mold, and other foreign materials—all of which can abrade or damage the grooves and diminish playback sound quality. Surface contamination can also occur when touching the grooves of a cylinder while handling it. Celluloid-based cylinders are prone to brittleness, and their cores (whether plaster or cardboard) are extremely fragile.

- Risk Level

- Cylinders should be given priority for reformatting because of the age, fragility, obsolescence, and relative uniqueness of their content.

- Playback

- Cylinders require format-specific machines for playback. Cylinders of different diameters cannot be played on the same machine; and, attempting to do so will damage the cylinder. The earliest cylinders are typically 2 to 2.5 minutes in length with 100 grooves per inch. Playback speed is also a consideration, since cylinders have different rotation speeds depending on the manufacturer and technology. Rotation speeds include 120 rpm, 144 rpm, and 160 rpm.

- Background

- Cylinders are the earliest manufactured recorded sound format. They were developed by Thomas Edison in 1877 and remained in commercial production until 1929. "Indestructibles" are the most common of the 2-minute celluloid cylinders. The Indestructible Record Company produced plastic cylinders from 1907 to 1922 that were in direct competition with Edison’s Amberol plastic cylinders. Blue Amberol was the trademark name for cylinders manufactured by the Edison company in the US from 1912 to 1929. These cylinders were easily recognized by their blue tint. Edison's company also produced Royal Purple Amberol cylinders.

- Storage Environment

-

Allowable Fluctuation: ±2°F; ±5% RH

Ideal Acceptable Temp. 40–54°F (4.5–12°C) 33–44°F (0.5–6.5°C) RH 30–50% RH - Storage Enclosure(s)

- Archival quality boxes are available specifically for cylinders. These are small, acid-free boxes that often have a cylindrical baffle inside, on which the cylinder is placed to secure it within the box. Cylinders should be stored in containers designed to support them vertically, bearing the weight at the bottom and protecting the surface from any pressure or contact with the container.

- Storage Orientation

- Cylinders should be stored standing on their ends like a drinking glass. Wood cabinets should be avoided. Enameled steel, stainless steel, or anodized aluminum are preferred.

- Handling/Care

- Cylinders should only be handled on the inside and at the top and bottom edges. Never touch the grooves on the cylinder exterior. If you must handle, insert two (or more) fingers into the cylinder interior and then use your other palm to support the bottom edge. Never leave media in a playback machine; always return to storage enclosure when not in use.

Resources

- Farrington, J. (1991). Preventive maintenance for audio discs and tapes. Notes, 48(2), 437-445.

- Library of Congress. (2002). Care, handling, and storage of audio visual materials. Retrieved from: http://www.loc.gov/preservation/care/record.html

- Stauderman, S. (2003, July 24-26). Pictorial guide to sound recording media. Paper presented at the symposium on Sound Savings: Preserving Audio Collections. Association of Research Libraries, Austin, TX. Retrieved from: http://www.arl.org/storage/documents/publications/sound-savings.pdf

- Warren, R. Jr. (1993). Storage of sound recordings. ARSC Journal, 24(2), 130-158.

- For additional resources, see Audiovisual (General) and Recorded Sound.