Preservation Self-Assessment Program

Office Printing and Reprography

"Reprography" is a category that includes copying and duplication processes. Copying, in this arena, refers to the production of a small batch of copies from an original. Duplicating, which encompasses printing processes, refers to the reproduction of virtually limitless copies. Since the emergence of digital tools, the distinction between the two has become less clear as hardware and software utilize and blend both.

Office Printing and Reprographic Processes

"Ink" on Paper

- Carbon Copy (1870s – 1980s)

- Stencil Copy (1880s – 1970s)

- Typography (c. 1902 – c. 1970)

- Offset Lithography (Office) (1906 – present) | cf. Offset Lithography (Photo) | Note: This is a different type of lithography than Gel-Lithograph.

- Impact Print (1960s – present)

Dye-Ink Transfer

- Hectograph Copy (Office) (1878 – 1970s) | cf. Hectograph Copy (Architecture)

- Spirit Duplicate (1923 – 1970s)

Photographic

- Photostat Copy (Office) (1909 – 1970s) | cf. Photostat Copy (Architecture)

- Diffusion Transfer (1940 – c. 1970)

- Dual Spectrum (1963 – early 1970s)

Electrostatic

- Electrostatic Xerox Copy (Office) (1949 – present) | cf. Electrostatic Print (Architecture)

- Color Photocopy (1973 – present)

- Laser Print (Office) (c. 1978 – present) | cf. Laser Print (Photo)

Other Processes

- Copybook and Roller Copy (1840s – 1950s)

- Diazo Print (Office) (1930s – present) | cf. Diazo Print (Architecture)

- Thermal Print / Thermofax (1950 – present; office use, 1950 – 1980s)

- Electrofax (1954 – 1980s)

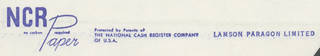

- Carbonless Copy (NCR) (1954 – present)

- Inkjet Print (Office) (1984 – present) | cf. Inkjet Print (Photo)

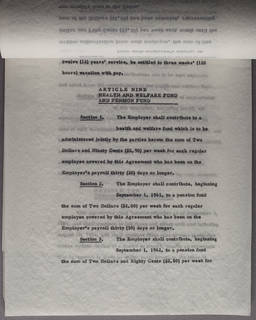

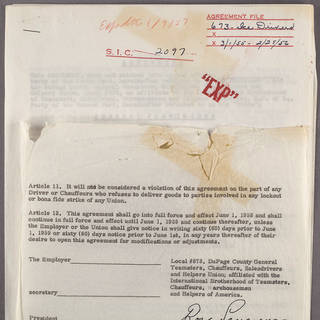

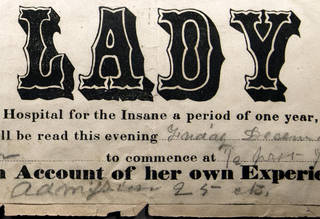

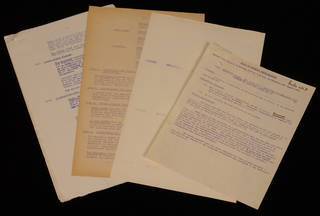

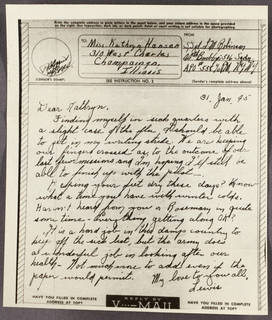

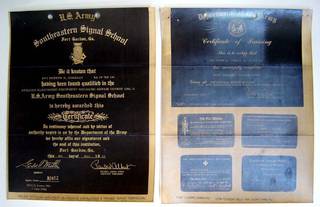

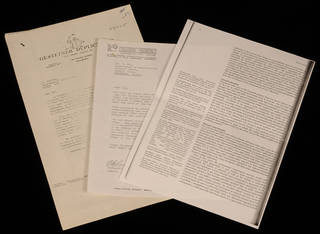

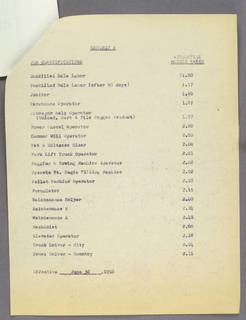

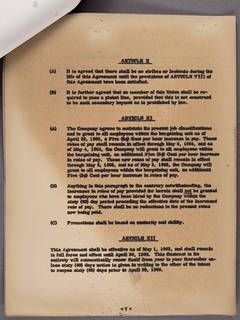

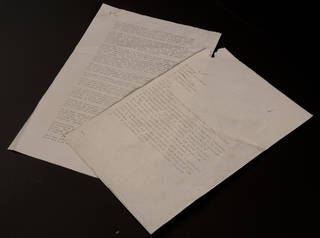

Carbon Copy

- Synonyms

-

- Carbon paper

- Manifold copy

- Onionskin copy

- Dates

- Patented 1806, popular 1870s – 1980s

- Prevalence

- Very common

- Support

- Thin, semi-translucent paper (tissue, onionskin, manifold)

- Paper Fibers

- Visible

- Paper Color

- White or canary

- Image/Text Tone

- Monochrome (black, blue, violet, or red)

- Description

-

Carbon copies may be typewritten or handwritten. Although it can come in nearly any color, carbon copy text will always be of a single color; and, the text will tend to be faint and dull. Black text is generally carbon pigment in a wax or oil base, and it will appear unfaded. Color text is aniline dye-based (likely blue, violet, red); these will often exhibit fading. Aniline dyes were used in both typewriter color ribbon and carbon papers (purple, blue, red inks). If the sheet bears more than one ink color and is opaque, it is likely the original top copy and thus not technically a carbon copy. Carbon copy text will lack the embossed quality of the directly typewritten top copy.

Carbon copies are usually made on crisp, semi-translucent paper. Because it is essentially a thin tissue paper, carbon copy paper wrinkles easily but is actually quite strong. This paper may either be made of durable rag-stock ("onionskin") or a low-grade wood pulp (manifold paper). It typically is a white or canary color with an unglazed, sometimes cockled surface. Image and/or text will be slightly waxy or greasy; it will appear to float on the paper surface when viewed under low magnification. Each successive layer in the copy set will be appear more blurry, with ever lessening contrast. Copies tend to smudge very easily. When carbon copies are found along with their corresponding top copy sheet, this usually indicates that it was an outgoing document.

- Composition

-

Support Image/Text Paper (uncoated) Wax- or oil-based carbon black or color ink (w/ aniline dye) - Deterioration

- Copies in black are generally carbon black pigment with a wax or oil base, and they are therefore stable. Any color other than black may be water-soluble and should be considered very light sensitive. Color ink may appear faded. Smudged image and/or text is common in either case. Manifold copy papers are composed of a low-grade wood pulp, which is very thin and weak and which should be assumed acidic. Onionskin copy papers are far more stable supports because they are made from cotton fiber.

- Risk Level

- Low. Black ink carbon copies (carbon black pigment) are low risk; color ink (aniline dye-based) copies are at a higher risk, but still rather stable. Copies on an acidic manifold paper support is of higher preservation priority than the relatively stable onionskin paper.

- Process

- Carbon paper is a duplication process, as copies are created at the same time the original is drafted. The carbon sheet, which has been back-coated with "ink" (pigment and oil/wax), is placed behind the original draft, with a sheet of copy paper (onionskin or manifold) behind them. If more than one copy is desired, additional carbon sheets are sandwiched between copy papers. Through the pressure of typewriter glyphs, a pen, or stylus, the pigment-and-wax "ink" is transferred to the copy paper(s) positioned behind the carbon sheet(s).

- Background

- Carbon paper was patented by Ralph Wedgwood as part of his Manifold Stylographic Writer system in 1806. This system was designed to make simultaneous copies of handwritten documents. The process was later marketed as a "copy book" or Stylograph. Carbon paper was frequently used to make copies of typewritten documents. Carbon copies are among the most common reprographic formats found in 20th century paper collections.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Carbon copies should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Black ink copies are generally quite stable and may be displayed. They should not be exposed to more than 30,000+ ft-c hours (300,000 lux hours) per year, and they should have a 1-year rest between displays. Color ink copies made using aniline dyes are highly sensitive to light. They should not be exposed to more than 5,000 ft-c hours (50,000 lux hours) per year, and they should have a 3-year rest between displays.

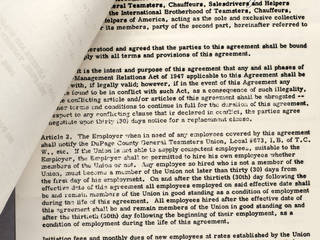

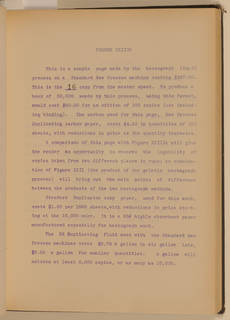

Stencil Copy

- Synonyms

-

- Cyclostyle

- Mimeograph

- Dermaprint

- Dermatype

- Gestetner

- Trypograph

- Papyrograph

- Roneo

- Edison autographic press

- Edison Electric Pen

- Dates

- 1880s – 1970s

- Prevalence

- Common

- Support

- Plain, fibrous paper

- Paper Fibers

- Visible

- Image/Text Tone

- Monochrome (carbon black, blue, violet)

- Description

- Stencil copies are usually printed on rough and porous plain paper with evident fibers, which provided optimal ink absorption. Image/text is often in black ink, but sometimes color dye inks (typically blue or violet) are used. Oil-based ink will cause slight toning around the printed image/text (a "halo" effect). Stencil images/text will have a clotted or stippled appearance. Closed characters (e.g. "o," "8") may appear as ink blobs due to stencil fall-out. As this is a wet ink process, ink streaking and "ghosted" reverse text may have transferred to the sheet verso from a previous (wet) print in the stack. Print quality may also bear resemblance to that of a spirit duplicate and hectograph, particularly those made with aniline color ink.

- Composition

-

Support Image/Text Paper (uncoated) Oil-based carbon black or color ink (w/ aniline dye) - Deterioration

- Oil-based inks produce relatively stable image/text. The water-soluble inks of early stencil copies, which often contained ink carriers (e.g. glycerine) and aniline colorants, make for very unstable prints. Permanence will depend greatly upon the quality of the paper support.

- Risk Level

- Low. Color prints on poor-quality support present a higher risk. Permanence will depend greatly upon the quality of the paper support.

- Process

- All stencil copying/duplication processes are essentially the same. To print a positive copy, a stencil is produced by reduction and then ink is forced through this stencil using pressure applied with a squeegee, roller, flat-bed press, or drum. The means of stencil creation will vary from freehand perforation by pen in the nineteenth century to mechanical reduction (e.g. typewriter, thermal, computer-aided) in the twentieth century.

- Background

- Stencil duplication is a broad category encompassing all processes that involve ink-and-stencil printing. Originally a method of manuscript copying using Cyclostyle and Neostyle pens in the 1870s, stencil duplication became commercially viable in the 1880s with the introduction of the mechanized Mimeograph process, allowing typewriters to create stencil masters. From then throughout the twentieth century, stencil copy was chiefly focused on typescript, when rotary stencil machines (e.g. Mimeograph, Gestetner, Roneo) appeared. Stencil machines were a common and economical printing method for small print runs in office, school, and church settings. Early fanzines were also often printed this way. By the 1970s, stencil copying had more or less been phased out by photocopying and offset printing. In some corners of publishing, use of stencil machines still persists today, albeit prepared digitally.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Stencil copies should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Black ink copies are generally quite stable and may be displayed. They should not be exposed to more than 30,000+ ft-c hours (300,000 lux hours) per year, and they should have a 1-year rest between displays. Color ink copies made using aniline dyes are highly sensitive to light. They should not be exposed to more than 5,000 ft-c hours (50,000 lux hours) per year, and they should have a 3-year rest between displays.

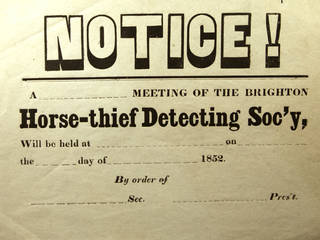

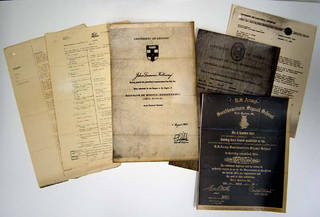

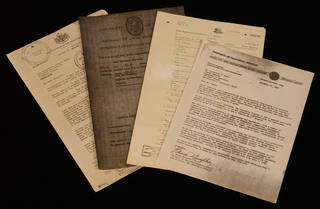

Typography

- Synonyms

-

- Letterpress

- Multigraph

- Typographic copying

- Dates

- c. 1902 – c. 1970

- Prevalence

- Moderately rare

- Support

- Varies in color, type, and size; did not require specialized paper.

- Paper Fibers

- Visible

- Image/Text Tone

- Carbon black or color ink (blue, violet, red)

- Description

- Typographic copies are difficult to distinguish from typed originals, stencil copies, hectographs, lithographs, and spirit duplicates. Ink used for typographic printing was typically oil-based carbon black, but it could be any standard printer ink. The text of typographic copies appears neat, well-spaced, and crisp since it is set from type. Due to the pressure of the printing process, typographic copies will typically exhibit more visible embossment, especially of smaller characters, on their verso side. As this is a wet ink process, ink streaking and ghosted reverse text may have transferred to the sheet verso from a previous (wet) print in the stack. Oil-based ink will cause slight toning ("halo") around the printed image/text. Text will most likely be black but is possibly violet, blue, or red. Often used for forms or promotional materials, typographic copies were usually produced in large quantities.

- Composition

-

Support Image/Text Paper (uncoated) Oil-based carbon black or color ink (w/ aniline dye) - Deterioration

- Carbon black text copies will present little to no preservation issues other than those of the paper support. Colored inks will likely contain aniline dyes and therefore will be prone to fading and running, in the case of water exposure.

- Risk Level

- Low. Black copies made with carbon black pigment are a low preservation risk. Color copies are a moderate preservation risk, due to the light and water sensitivities of aniline dyes.

- Process

- Typographic copies were produced on flat-bed or rotary machines. In flat-bed machines, individual letters of type were composed and locked into a flat plate, which was then inked. Paper placed against the inked plate would produce a copy of the set type. Rotary presses worked in the same manner, but with the type set around the outer surface of a drum rather than a plate. Rotary presses were turned by a crank or electric motor. Some typographic copy machines like the Addressograph and Addressing Multigraph were designed specifically for addressing correspondence. These machines used embossed metal plates rather than moveable type.

- Background

- Typographic copying, or letterpress printing, had limited office applications from about 1902 to 1970. Typographic copy machines designed for office use were small-scale letterpress machines that made small runs of copies. The Multigraph was the earliest typographic copy machine; it made copies using moveable type and carbon paper. Later typographic copy machines include the Roneotype, Printograph, and Planotype.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alkaline storage enclosures are not advised for typographic copies, which may contain aniline dyes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Letterpress prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Black ink copies are generally quite stable and may be displayed. They should not be exposed to more than 30,000+ ft-c hours (300,000 lux hours) per year, and they should have a 1-year rest between displays. Color ink copies made using aniline dyes are highly sensitive to light. They should not be exposed to more than 5,000 ft-c hours (50,000 lux hours) per year, and they should have a 3-year rest between displays.

Offset Lithography (Office)

- Synonyms

-

- Offset litho

- Multilithing

- Rotaprinting

- Offset duplication

- Offset printing

- Photo-offset

- Dates

- 1906 – present; office use declines after 1960s

- Prevalence

- Common in general printing applications. Moderately rare in office applications.

- Support

- Plain paper

- Paper Fibers

- Visible

- Image/Text Tone

- Monochrome (carbon black or numerous other color inks)

- Description

- Lithographic copies may include handwriting, typescript, or graphic material. Oil-based inks will cause slight toning around the printed image/text (a "halo" effect). Lithography, or some derivative form, is the process by which most commercial and widely distributed textual material was printed in the twentieth century. Since its use as an office printing process was modest, its identification as such, in terms of preservation, is not essential. Early forms of office lithographic copies (text) are difficult to differentiate from stencil copies. They will be qualitatively identical to most oil-based carbon black inks, and they are therefore stable.

- Composition

-

Support Image/Text Paper (uncoated) Oil-based carbon black or color ink (w/ aniline dye) - Deterioration

- Oil-based ink is fairly stable and is water insoluble. Carbon black ink will be resistant to fading. Other colors will likely contain aniline dyes (water-soluble); they will therefore be prone to light-fading and running if exposed to either water or extremely high humidity.

- Risk Level

- Moderately low. Low (black ink) to moderate (color inks). Permanence will depend greatly upon the quality of the paper support.

- Process

- Lithographic printing is based on the principle that water and oil do not mix. All lithographic processes involve a printing plate that is treated such that oil-based ink adheres to the image/text areas and is repelled by the non-image/ text areas. The plate may be paper or plastic (for making just a few copies), or aluminum or zinc (most common; for larger runs of copies). The surface of the plate was then treated to make it attract water, such as by applying gum. The image/text was applied in a variety of ways using oil-based ink, such as by typing directly onto the plate or using a prepared stencil master to stencil the image. A blank piece of paper applied to the plate with some pressure then yields a copy.

- Background

- Early lithography was invented by Alois Senefelder in 1798 and was done on metal. While lithography is most synonymous with fine art reproduction, offset paper lithography has been used in commercial and office settings for over 100 years. Offset lithography on paper was introduced around 1906 and was popular for industrial-level printing and the rapid production of large runs of material. Compared to other printing processes, offset lithography is best suited for producing large volumes of high-quality prints. However, offset copying machines like the Autocopyist and the Roneo-Litho were also produced for use in offices in the early twentieth century.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Ideal Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Offset lithographic prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Black ink copies are generally quite stable and may be displayed. They should not be exposed to more than 30,000+ ft-c hours (300,000 lux hours) per year, and they should have a 1-year rest between displays.

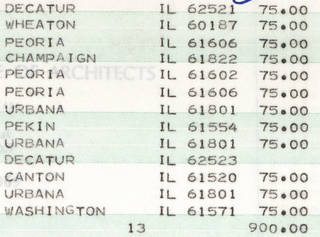

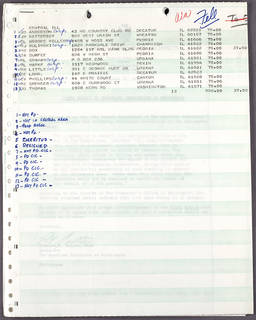

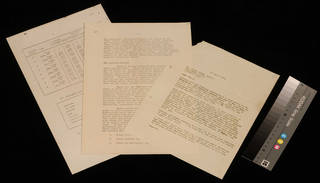

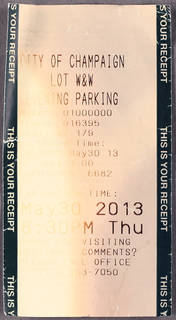

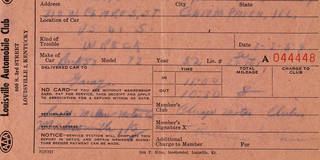

Impact Print

- Synonyms

-

- Dot-matrix print

- Daisy wheel print

- Line print

- Dates

- 1960s – present

- Prevalence

- Fairly common

- Support

- Plain copy paper

- Paper Fibers

- Highly visible

- Image/Text Tone

- Monochrome (black [most common], blue, violet, red)

- Description

- Impact prints are qualitatively (and often chemically) similar to any typewritten document, although they often come from a digital source. In fact, daisy wheel technology was used in both computer printers and electronic typewriters of the 1970s and 1980s. Characters from an impact printer will either appear as: crisp, well-defined glyphs (if from a daisy wheel printer), oddly-aligned rows (if from a line print), or comprised of evenly spaced, fuzzy dots (if from a dot-matrix printer). On close inspection, the ink appears penetrate the paper and the paper fibers are visible through the ink. "Black" text will likely appear gray-black. Color text is less common, but text using blue, violet, or red ink can be found. Color impact printing generally looks faded, streaky, and sometimes smeared. Dot-matrix printers are still used for tickets or receipts. Daisy wheel printers, which are now obsolete, were generally used for high-quality print applications where presentation was a consideration (i.e. in offices).

- Composition

-

Support Image/Text Paper (uncoated) Wax- or oil-based carbon black or color ink (will contain aniline dyes) - Deterioration

- Stability will vary depending on the ink. Oil-based or wax-based ink carrying a black pigment will be relatively stable, whereas water-based ink carrying a colored aniline dye will be far less stable. Continuous feed paper stock used in dot-matrix and line printers were often wood-free, meaning that the lignin had been removed; yellowing and/or embrittlement of the paper is therefore rare.

- Risk Level

- Low. Black ink is a carbon-based pigment and is fairly permanent. Color inks should be assumed water-soluble and not stable. Dot-matrix and line prints will often hold up well, having avoided yellowing and embrittlement due to the lack of wood in their paper stock.

- Process

- Impact prints are copies produced from an electronic file rather than a hard-copy original. Impact prints may be created using one of three types of prints: dot-matrix, daisy wheel, or line printers. Similar to typewriters, all use an inked ribbon that transfers ink to paper via impact on the ribbon. The resulting prints are generally of a lower quality than those produced using inkjet or laser printers, but they are also cheaper.

- Background

- Impact printers were commonly used in offices in the 1960s and 1970s, and they continued to be popular as use of personal computers increased in the 1980s. Impact prints were an inexpensive method of printing from an electronic file. Throughout the 1990s, impact printers became less popular as the use of laser and inkjet printers increased. Use of dot-matrix printing persists in many forms, although it is primarily now used for compact, low-end applications like printing tickets and receipts. Full-size dot-matrix printers utilizing tractor feed paper are also still used to print multi-part stationery for businesses like banks and auto repair shops.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Impact prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Black ink copies are generally quite stable and may be displayed. They should not be exposed to more than 30,000+ ft-c hours (300,000 lux hours) per year, and they should have a 1-year rest between displays. Color ink copies made using aniline dyes are highly sensitive to light. They should not be exposed to more than 5,000 ft-c hours (50,000 lux hours) per year, and they should have a 3-year rest between displays.

Hectograph Copy (Office)

- Synonyms

-

- Gelatin duplication

- Jellygraph

- Anilin process (sic)

- Chromograph (in UK)

- Composition pad

- Copygraph

- Gelatine pad

- Dry copy

- Hektograph

- Polygraph

- Dates

- 1878 - 1970s

- Prevalence

- Fairly common

- Support

- Plain paper, often with gelatin or alum/rosin sizing agent.

- Paper Fibers

- May or may not be visible, depends on paper coating

- Image/Text Tone

- Monochrome (violet or blue, sometimes other colors)

- Description

- Hectograph image/text is commonly a violet or blue color that is made from aniline dyes. The paper is often bright white with a smooth, heavily finished surface to control ink use. Hectography was used for both handwritten and typewritten documents, and it was often used to duplicate course materials and publications for small clubs and churches. Technical drawings and graphic art were seldom duplicated in this fashion. Hectographs are nearly indistinguishable and chemically similar (aniline ink) to diazos and spirit duplicates.

- Composition

-

Support Image/Text Paper with gelatin or alum/rosin sizing Aniline dye ink - Deterioration

- An image/text composed of aniline dye ink is light sensitive and to some extent water soluble. Alkaline enclosures and treatments will cause discoloration due to the pH sensitivity of aniline dye. Residual acidic processing chemicals on the copy paper could accelerate breakdown. Alum/rosin sizing, which is impregnated in most copy papers, will lead to embrittlement and yellowing of the paper support; high temperature and relative humidity will accelerate deterioration. Permanence will depend greatly upon the quality of the paper support.

- Risk Level

- Moderate. Aniline dyes are sensitive to light and water. Alkaline enclosures should be avoided. Permanence will depend greatly upon the quality of the paper support.

- Process

- Hectographic duplication involved typing or writing a master document in hectographic (aniline) ink. Once dry, the master would be pressed face down onto the gelatin-and-glycerin pad surface and left to allow the ink to transfer as a negative image. An alternate method for applying ink to the pad involved the use of a stencil. In either case, the pad was then pressed in contact with copy paper, which absorbed the aniline ink, resulting in a final positive copy. Hectographs could typically produce 40 to 60 copies, each successively lower contrast than the preceding copy.

- Background

- The hectographic process emerged as a result of the introduction of aniline inks. It became common as an office duplication process around 1878. Hectographs at that time were regarded as the most practical method of office reprography and rose in public favor quickly. By the mid-twentieth century, hectography was a common and economical printing method for an array of limited run applications (i.e. office copies, classroom materials, and church ephemera). Early fanzines were also printed this way. Hectography was gradually displaced by spirit and stencil duplication beginning in the 1950s and altogether phased out by photocopying in the 1970s.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alkaline storage enclosures are not advised for hectographs. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Hectographs should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Hectographs were made using aniline dyes that are highly sensitive to light. They should not be exposed to more than 5,000 ft-c hours (50,000 lux hours) per year, and they should have a 3-year rest between displays.

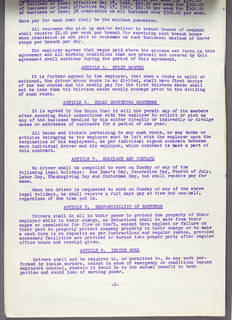

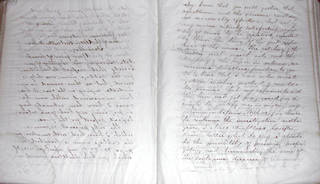

Spirit Duplicate

- Synonyms

-

- Ditto copy

- Liquid hectograph

- Hectograph spirit duplicating

- Roneo

- Dates

- 1923 – 1970s

- Prevalence

- Fairly common

- Support

- Plain paper, often with gelatin or alum/rosin sizing agent

- Paper Fibers

- May or may not be visible depending on support paper

- Image/Text Tone

- Monochrome (violet, blue, or black)

- Description

- Image/text color most often purple ("crystal violet") but may be blue or black. The image/text was formed using aniline dye in wax (soluble in a hydrocarbon spirit). Background is white or slightly tinted, with a heavily finished, glossy surface (to control ink use) and visible paper fibers. Spirit duplication was mostly used to copy typewritten documents; handwriting and drawings are common, but less so. "Dittos" were used for both handwritten and typewritten documents, often used to duplicate course materials and small-run church and club organizational publications. Copied text lacks the embossed quality of original typescript; characters will lack crisp edges, and they can appear alternatively blotted or ghostly. Spirit duplicates bear strong resemblance to hectographs, including the "crystal violet" color and tendency of characters to appear fuzzy.

- Composition

-

Support Image/Text Paper treated w/ gelatin or alum/rosin sizing Aniline dye in wax - Deterioration

- Aniline dye ink is very light sensitive and therefore prone to fading over time. Aniline dyes, even in a wax-based ink, may run when exposed to water. Alkaline enclosures and treatments should be avoided as they might cause discoloration due to the pH sensitivity of aniline dye. Paper discoloration is common and may also result in an overall lower contrast.

- Risk Level

- Moderate. Under intense UV light, spirit duplicates can fade to illegibility in less than a month. The common paper support is of low quality, and will yellow and become brittle due to residual acid. At its worst, these copies can literally crumble into small particles when handled.

- Process

- The negative master is produced by writing or typewriting on a sheet backed with carbon pigment and aniline dye suspended in a wax binder. The dye component is soluble in alcohol-based fluid and is transferrable by pressure. The master is then a reverse image of the text, which is fastened to the cylinder of a rotary printing surface, with the the ink image facing outward. Copy papers wetted with the duplication fluid ("spirit") are then run under the cylinder, at once dissolving and transferring the ink to their surface.

- Background

- A spirit duplicate is typically referred to as a "ditto" copy. The process is considered the evolution of the hectographic process and was invented by Wilhelm Ritzerfeld in 1923. By the mid-twentieth century, spirit duplication was a common and economical printing method for small organizations printing in limited quantities (i.e. office copies, classroom materials, club newsletters, and church ephemera). Early fanzines were also produced this way. Instead of an ink-transmitting gelatin pad, spirit duplication incorporates a waxy, paste-like ink that is partially dissolved with the application of a hydrocarbon spirit solvent. Over time, some of the chemicals involved were understood to be very unsafe. By the 1970s, spirit duplication was replaced by photocopying and offset printing.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alkaline storage enclosures are not advised for spirit duplicates. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Spirit duplicate prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Spirit duplicates were made using aniline dyes that are highly sensitive to light. They should not be exposed to more than 5,000 ft-c hours (50,000 lux hours) per year, and they should have a 3-year rest between displays.

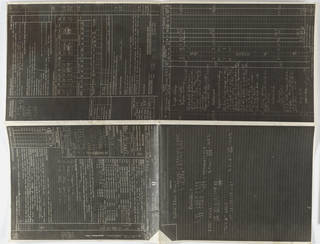

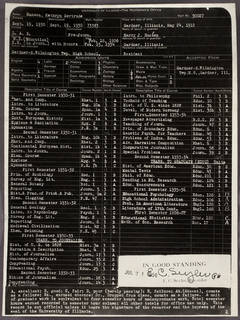

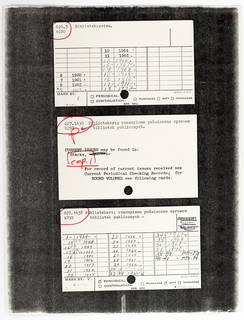

Photostat Copy (Office)

- Synonyms

-

- Photostatic Print

- Rectigraph

- Dates

- 1909 – 1970s; use declines after 1950

- Prevalence

- Fairly common

- Support

- Sensitized photographic paper (without baryta layer)

- Paper Fibers

- Not visible

- Image/Text Tone

- Monochromatic white text on black background (negative image) or black text with white background (positive image)

- Description

- The image may be negative or positive, although negatives (white image/text on black background) are more common. Similar to silver gelatin prints, the image/text is comprised of silver particles. Copies are qualitatively similar to silver gelatin black-and-white photographs, including the tendency to exhibit silver mirroring. The paper is thinner than most photographic paper, since it lacks a baryta layer and has thinner emulsion. Copies may have rough edges and occasionally odd dimensions because they were cut from rolls.

- Composition

-

Support Binder Image/Text Paper (specially coated) Gelatin Silver - Deterioration

- Preservation of photostatic prints is nearly identical to the preservation properties of silver gelatin DOP prints. For more information, see Silver Gelatin (DOP)Print. Like other silver images, photostats are very sensitive to light and will fade through prolonged exposure. Similarly, they are prone to silver mirroring and may yellow significantly, especially if they were not properly processed or washed.

- Risk Level

- Moderately low. Protect photostats from prolonged light exposure as they are as photosensitive as any silver gelatin print.

- Process

- Photostat copy machines were basically large cameras that used a prism to produce a right-reading image. Each exposure produced one print, usually a negative (black background with white text). In 1953, Kodak released a direct-positive paper, allowing for the production of positive copies from a positive original. A positive image could also be produced by creating a negative copy and copying the negative again to create a positive copy. After exposure, the paper was cut from the roll and placed in a developing bath beneath the camera, then a fixer bath. The print was then washed in water, with excess water removed using a squeegee after taking the print out of the final bath. The print was finally dried by pressing between blotters, passing through a set of heated rollers, or dried face-down on glass (this would result in a glossy finish).

- Background

- Photostatic prints mark the beginning of true copies made through photographic methods. The Rectigraph, which was manufactured in Rochester, NY beginning in 1909, was the first commercially produced photostatic copy machine. The Rectigraph company later became the Rectigraph Division of Haloid in 1937, and later still Haloid-Xerox in 1958. The company was merged into the Xerox Corporation in 1961. The Photostat copy machine was developed by Photostat Ltd. shortly after the Rectigraph. Two other photostatic copy machines, produced specifically for the reproduction of library catalog cards, were the Photoclerk (Anken Chemical and Film Corporation) and Dexigraph (Remington Rand). Photostatic copy machines were large and required a specialist operator. The Photostat was so popular during the height of its use that the name became a common noun to refer to all copies produced by a photostatic copying process.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Photostatic prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

If the print appears well-processed and stable, it may be displayed for up to 30,000+ ft-c hours (300,000 lux hours) per year with a 1-year rest between displays. Photostat prints were often poorly processed, however, so a more conservative approach to display may be required (5,000 ft-c hours [50,000 lux hours] per year with a 3-year rest between displays).

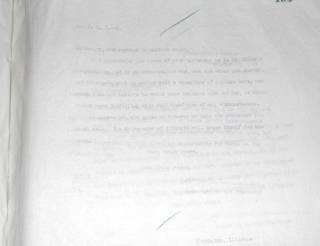

Diffusion Transfer

- Synonyms

-

- Diffusion transfer reversal

- Chemical transfer

- Reflex transfer Copyrapid (Agfa)

- Gevacopy (Gevaert)

- Verifax (Kodak)

- Diaversal

- Copyproof

- Dates

- 1940 – c. 1970

- Prevalence

- Moderately rare

- Support

- Specially-coated paper

- Paper Fibers

- May or may not be visible, depends on support paper

- Image/Text Tone

- Monochrome (black or brown)

- Paper Tone

- Light brown or gray/buff

- Description

- Gelatin layer sits on top of the paper with the dye components slightly penetrating the fibers, which is evident under low magnification (10x–30x). Sheets may bear the paper type or manufacturer’s backprint (e.g. Kodak, Gevaert, Agfa). Cut corners are also an identifier for Kodak papers, both for the positive and negative papers. Blotchy water staining and fingerprinting may also be apparent on the back. Image/text contrast may be low, especially for faded inks on a brown background. Diffusion transfers are bi-tonal and cannot reproduce continuous tone or halftone images well. Although a positive copy is considered the end product and focus of this profile, the intermediate negative may also sometimes be found among collections. Sheets have tendency to curl slightly. Diffusion transfer sheets are thicker than most thermally processed copies.

- Composition

-

Support Binder/Emulsion Image/Text Paper (specially coated) Gelatin Silver sulfide, silver halide, elemental silver - Deterioration

- Final copy is chemically similar to black-and-white gelatin silver photographs, therefore preservation aspects are also similar. What sets diffusion transfers apart is that they will often contain many residual chemicals, precipitating advanced staining, embrittlement, and silver mirroring. Sheets will have a tendency to curl slightly.

- Risk Level

- Moderate. Protect diffusion transfer prints from prolonged light exposure as they are as photosensitive as any silver gelatin print.

- Process

- Diffusion transfer copy process is a reflex method based on silver halide chemistry, similar to that of black & white gelatin silver photographs. Two sheets are used in the copy process: a photosensitive sheet with a silver gelatin emulsion and a sheet coated with a gelatin emulsion containing an image-fixing solution (sodium thiosulfate). In the process, light is reflected from an original sheet to make a negative image on the silver gelatin photo emulsion of another sheet. Once exposed to light, the negative copy is developed in an alkaline activator solution to develop/tan the emulsion, resulting in a differential hardening of the gelatin layer between the image and non-image areas. The image is then transferred through pressure to a special copy paper. This is the final copy: a positive image composed of alkaline gelatin, silver salts, reduced silver, thiosulfate and a dye.

- Background

- The diffusion transfer process was first developed in 1940 but was not popularly adopted until the 1950s. The three most popular brands of diffusion transfer products were Copyrapid (Agfa), Gevacopy (Gevaert), and Kodak, although other companies also produced diffusion transfer products. The process was closely related to direct photocopying and reflex photocopying, and it was an important precursor to the development of instant photography and the Polaroid land camera, which was first sold in 1949. By the end of the 1960s, the diffusion transfer process was rarely used in the document copying realm.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Diffusion transfer prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Although similar to silver gelatin photographs, diffusion transfer prints frequently contain residual chemicals, making them particularly sensitive to light. As a result, a conservative approach to display may be required of 5,000 ft-c hours [50,000 lux hours] per year with a 3-year rest between displays.

Dual Spectrum

- Dates

- 1963 – early 1970s

- Prevalence

- Fairly common

- Support

- Paper with acrylic coating

- Paper Fibers

- Not visible

- Paper Tone

- Pastel pink or cream colored

- Image/Text Tone

- Monochrome (dark red-brown or black)

- Description

- Dual spectrum copies can be identified by a distinctive flame emblem (usually light blue) on the verso of the final copy. Image/text is clear and sharp, ranging from dark red brown to black. The image/text could be copied from any original document, including those that were handwritten or typed by various methods. As a result, there is no uniform appearance to the text of dual spectrum copies, other than sharp quality of the image reproduction (unless it was produced from an original document of poor quality) and the text color. The paper ground may be pinkish or cream. The special coated paper used to create dual spectrum copies was available in a range of weights and varies from flimsy to bond weight.

- Composition

-

Support Binder/Emulsion Image/Text Specially coated paper Acrylic Metallic silver - Deterioration

- Dual spectrum prints are relatively stable and deteriorate in a manner similar to silver gelatin photographic prints. They may exhibit silver mirroring as a result of oxidation. The silver salts contained in the paper coating are somewhat acidic and may cause the paper support to deteriorate over time.

- Risk Level

- Moderate. Protect dual spectrums from prolonged light exposure as they are as photosensitive as any silver gelatin print.

- Process

- The dual spectrum process involves the use of two sheets. The first sheet is used to create a photographic copy of the original document. This intermediate sheet was made of thin Mylar or tissue paper and was coated with an oxidant and coupler. The sheet was placed in contact with the image side of the original and placed into the copy machine that exposed the composite from the film side to a powerful tungsten light. The coating on the sheet reacted with the light to produce an inert product, leaving a pattern of unreacted material corresponding to the original image. The exposed intermediate sheet was then placed in contact with a receptor sheet of paper with a coating of acrylic containing silver salt. The sheets were run past an infrared source (e.g. Thermofax copy machine). The unreacted areas of the intermediate sheet would heat up causing the oxidant to vaporise. The vaporized oxidant reacted to the silver salt in the receptor paper, producing a metallic silver image.

- Background

- 3M introduced the dual spectrum process in 1963. Although other companies marketed dual spectrum-style products, 3M was the primary manufacturer of dual spectrum copy machines and papers. The process was popular through the early 1970s and even overshadowed the Thermofax for some time. The dual spectrum process improved on the Thermofax process by making it possible to copy original written or printed material that had been made using non-metallic and carbon-based inks. However, the dual spectrum process was more complex and required two processing steps as well as an intermediate sheet to transfer the image.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Dual spectrum prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

If the print appears well-processed and stable, it may be displayed up to 30,000+ ft-c hours (300,000 lux hours) per year with a 1-year rest between displays.

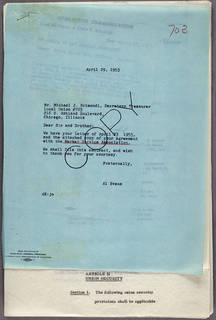

Electrostatic Xerox Copy (Office)

- Synonyms

-

- Photocopy

- Xerographic copy

- Electrophotography

- Plain paper electrostatic copy

- Dates

- 1949 – present; oversized copies from c. 1960 – present

- Prevalence

- Very common

- Support

- Plain copy paper; polyester transparency film also possible

- Paper Fibers

- Visible

- Image/Text Tone

- Monochrome (black)

- Description

- Electrostatic office copies like Xeroxs are nearly indistinguishable from other plain paper processes. Sometimes, the edges of the original scanned document can be seen in the electrostatic copy if not aligned exactly. Other image noise and artifacts can be picked up through subsequent copying at high contrast. The toner is made up of an inert resin and carbon black pigment. This is one of the most prevalent copy formats of the late twentieth century and at present. Photocopying is a commonly recommended, low-cost reformatting method for other at-risk documents in archival collections. Electrostatic copying and printing technology has also been implemented to produce oversized technical and architectural drawings. This application of indirect electrostatic copying began in the 1960s and persists today.

- Composition

-

Support Image/Text Paper (uncoated) or polyester transparency Black toner (carbon black pigment in resin) - Deterioration

-

Electrostatic Xerox copies tend to be very stable and image permanent since the toner is black carbon pigment in a resin carrier—both inert materials. Proper processing will ensure permanence but is dependent upon the quality of the paper.

Electrostatic copies should be stored at moderate temperature and relative humidity. Because the resin binders are thermoplastic polymers with low softening temperatures, avoid storage under conditions of heat and/or pressure. Experience has shown that the binder resins in xerographic copies are vulnerable to blocking to adjacent surfaces with heat or pressure. Contact with polyvinyl chloride plastic can cause softening and transfer to adjacent surfaces because of plasticizer migration from the plastic. A black Xerox copy can be expected to have good to excellent light stability, depending on the quality of the paper support.

- Risk Level

- Low. Store in a moderate environment. Avoid exposure to heat and pressure, in addition to polyester storage materials, as any one of them could cause toner loss and transfer to adjacent materials.

- Process

- Electrostatic copies are made through a five step process. First, a photoconductive selenium plate or drum is charged. The plate or drum is then exposed to a pattern of light from the original document, leaving only the image areas charged. A powdered toner is then applied over the plate or drum which only adheres to the electrostatically charged areas. The sheet of copy paper, which is given an electrical charge of opposite polarity to the plate or drum, is then brought in contact with the plate or drum thus transferring the image. The toner is fused to the paper with heat.

- Background

- The first commercial xerographic machines were produced by the Haloid Company (now Xerox Corporation) in 1949. The first machines were manual, with the first semi-automatic machine, the Copyflo, being released in 1955. Xerox released the first all-in-one copier, the Xerox 914, in 1959; and after that point, monochromatic electrostatic copying began to dominate the office copying market. Although additional single color toners were produced in the late 1950s, it was not until the Xerox 6500 color copier’s introduction in 1973 that full-color xerography arrived (see Color Photocopy). Since the 1960s, electrostatic copiers have remained the most popular office copying machine due to their simplicity and speed. Speaking to the prevalence of the copy process throughout the latter half of the twentieth century, Xerox'ed photographs are commonly found among paper documents.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Electrostatic Xerox prints should not be encapsulated or placed in polyester sleeves. Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Electrostatic Xerox prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets. If oversized, store flat (preferred) or rolled.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Light exposure during exhibition should be restricted, especially for dye-based copies and copies on zinc oxide coated paper. Electrostatic Xerox copies may be displayed up to 30,000+ ft-c hours (300,000 lux hours) per year with a 1-year rest between displays.

Color Photocopy

- Synonyms

-

- Color Xerox

- Electrostatic color copy

- Dates

- 1973 – present

- Prevalence

- Moderately rare

- Support

- Plain office copy paper or paper with polymer coating

- Paper Fibers

- Visible

- Image/Text Tone

- Color (CMYK)

- Description

- Cyan, magenta, and yellow toner layers may be noticeable under magnification. Like black-and-white electrostatic copies, color photocopies do not necessarily require specialized paper and can be printed on plain office copy paper. However, in order to optimize color and image clarity, papers with a polymer coating are often used for color photocopies. Polymer-coated paper may mimic photographic paper finishes, such as glossy, satin, and matte.

- Composition

-

Support Image/Text Paper (uncoated or coated) CMYK toner

(inert resin, colored pigments—cyan, magenta, yellow, and black carbon pigment) - Deterioration

- The preservation issues of color photocopies are largely dependent on the type of paper used. Paper with a polymer coating can be easily damaged through abrasion or flexing, and it commonly yellows. Due to the colored pigments used in CMYK toner/ink, the image will fade on light or water exposure. Xerox 6500 color copies appear to have a fairly good light stability.

- Risk Level

- Moderately low. Stability depends upon the ink quality, which varied greatly across manufacture lines and era.

- Process

- Color photocopies are produced using CMYK toners, the same process as xerography. Color photocopy machines use a drum that is reactive to the full visible spectrum. Early color copiers used multiple copy cycles, requiring multiple passes to be made for each color and using separate color filters and toners for each. Modern copiers perform a single scan to four miniature process units (CMYK) that operate simultaneously.

- Background

- The first electrostatic color copier was released by Xerox in 1973, although single color toner arrays were available as early as the late 1950s. Color copiers are still in use to the present day, but are very rare due to the rise of inkjet and laser color printing.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Electrostatic color prints should not be encapsulated or placed in polyester sleeves. Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Electrostatic color prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Color pigments are sensitive to light. Use of facsimiles for display is recommended. If color photocopies are displayed, they should be exposed to no more than 5,000 ft-c hours (50,000 lux hours) per year with a 3-year rest between displays.

Laser Print (Office)

- Dates

- c. 1978 – present

- Prevalence

- Common

- Support

- Plain copy paper or polyester transparency film

- Fibers (if paper)

- Visible

- Image/Text Tone

- Monochrome (carbon black) or color (CMYK)

- Description

- Laser printing is an electrostatic printing process that is nearly identical to the xerographic copy process—the difference being that laser prints come from a digital source (i.e. printed from a computer). Unlike the electrostatic photocopying processes, there are no visual artifacts or edges of an original document visible, and the text/image is square on the page. Laser prints can be made using the same toners as plain paper electrostatic copies. Prints may be black-and-white (black toner contains resin and black carbon pigment) or color (CMYK toner containing resin and four colored pigments—cyan, magenta, yellow, and black carbon pigment). Laser printing may also be used to produce oversized technical and architectural drawings.

- Composition

-

Support Image/Text Paper (uncoated) or polyester transparency Pigment-based toner (CMYK) - Deterioration

- Black-and-white laser prints tend to be very stable and permanent since the toner is essentially black carbon pigment in a resin carrier. Proper processing will ensure permanence, but is dependent upon the quality of the paper. Color laser prints may fade on light or water exposure due to the colored pigments used in CMYK toner/ink.

- Risk Level

- Low. Color prints are a higher preservation risk.

- Process

- The laser printing process is similar to electrostatic copying, but instead of copying an image from a hardcopy document, the image is transferred from an electronic file via laser. A drum is electrostatically charged with a laser that transfers the image to be printed. The charged areas of the drum picks up toner, which is then transferred to the paper and set with heat.

- Background

- In the late 1970s, laser printers became common for printing from mainframe computers in offices. Color laser printers and copiers emerged in the late 1980s, becoming common with desktops in the early to mid-1990s. At the same time, laser printing became economical for use with personal computers, and it had become widely used by the end of the twentieth century. The HP Laserjet printer product line is often associated with consumer-grade laser printing technology today. Along with inkjet and impact printing, laser printing is one of the three main processes accounting for all copies from electronic files at the end of the twentieth century.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Laser prints should not be encapsulated or placed in polyester sleeves. Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Laser prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Laser prints should be exposed to no more than 5,000 ft-c hours (50,000 lux hours) per year with a 3-year rest between displays.

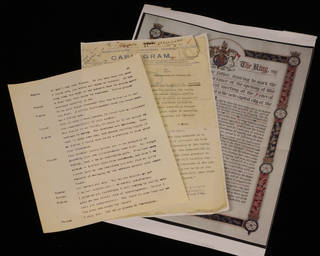

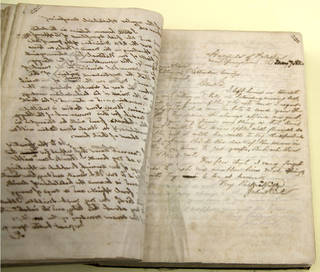

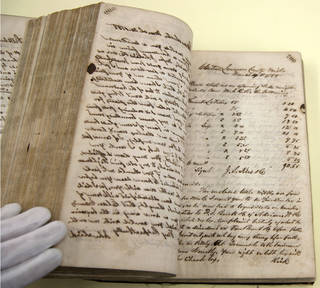

Copybook and Roller Copy

- Synonyms

-

- Letter book

- Letterpress copybook

- Pressed letter process

- Glutinous ink process

- Dates

- 1840s – 1950s

- Prevalence

- Common

- Support

- Very thin, translucent paper

- Paper Fibers

- Visible

- Image/Text Tone

- Violet, blue (aniline ink); brown (iron gall ink)

- Description

- Handwritten letters are most common, but letterpress copybooks also exist. Copybook copies are on thin, translucent plain paper. Image/text will be visible through both sides of the thin tissue as the ink has bled through. Image/text will appear to feather along the edge. Most inks or copy pencils colored with aniline dye will be violet or blue. Early iron-gall based inks will appear brown. Paper fibers are visible under low magnification (10x–30x). Before 1856, copies were created with iron-gall ink modified with sugars or glycerin. After 1856, glutinous aniline ink pens were widely adopted. In 1875, copy pencils colored with aniline dye, often violet or blue, were commercially introduced.

- Composition

-

Support Image/Text Paper (uncoated) Aniline, iron gall, or carbon black pigment ink - Deterioration

- Although thin, most copying papers were comprised of long cotton fibers, but linen and silk were also sometimes used. These papers are relatively stable and have a low preservation risk. Less common are low-grade wood pulp papers, which were often treated with sulphuric acid to optimize translucency of the paper, leading to severe weakening or embrittlement over time. This acidity may migrate to adjacent sheets. Iron-gall ink will be prone to lacing. Aniline dyes are unstable under light and will fade easily; aniline is also water soluble.

- Risk Level

- High to moderate. Preservation risk depends on the composition of the ink and paper used. Low-grade wood pulp papers are susceptible to easy tearing, fragmenting, and, in combination with iron gall ink, burn-through and lacing. Higher quality cotton, linen, and silk papers are lower risk. Aniline dye-based ink is water-soluble and fades; iron gall ink corrodes and eats through paper; but, carbon black pigment is by all accounts stable.

- Process

- The copy was produced by placing the original letter against a water-moistened tissue, which either was bound in a copybook or was part of a copier roll that was later cut into sheets. Then, the letter would be pressed in a copying press mechanism (screw, roller, or cantilever press). Copybooks could normally only produce a single copy whereas roller copiers could produce as many as six from the original letter.

- Background

- Invented around 1780, the copybook did not become a popular office reprographic method until the 1840s. Copybooks of one form or another were used through the 1950s. The combination of the typewriter and carbon papers displaced copybooks.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Copybooks should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-

Responsible display practices ensure the long-term preservation of collections. Facsimiles should be used whenever possible, and paper artifacts should not be displayed permanently. Light levels in the exhibition area should be kept low. Appropriate filters should be used to minimize exposure to ultraviolet light. Display cases should be enclosed and sealed to protect their contents, and their items should be securely framed or matted using preservation-quality materials that have passed the Photographic Activity Test (ISO 18916:2007).

Copybook copies contain dye- or iron-based inks which are highly light sensitive. Low-grade paper will deteriorate more rapidly if exposed to UV light. If copybook copies are displayed, they should be exposed to no more than 5,000 ft-c hours (50,000 lux hours) per year, with a 3-year rest between displays.

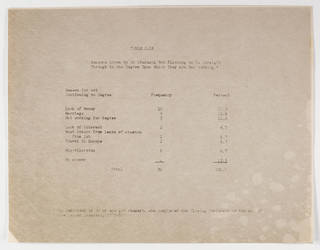

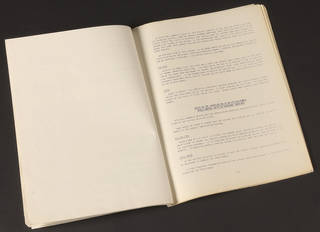

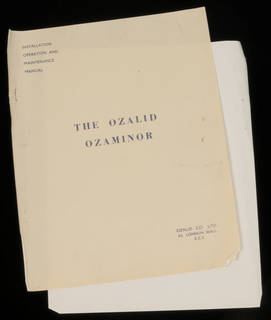

Diazo Print (Office)

- Synonyms

-

- Diazotype

- Whiteprint

- Azograph

- Ammonia print

- Gas print

- 3M dry diazo

- Azoflex (Ilford)

- Direct print

- Dyeline

- Blueline; Blackline

- Ozalid

- Dates

- 1930s – present; office use, 1940s - 1970s; technical use, 1920s - 1970s

- Prevalence

- Moderately rare

- Support

- Plain or coated paper

- Paper Fibers

- Visible under low magnification

- Image/Text Tone

- Monochrome (deep blue, purple, black, or brown)

- Description

- The diazo print is the result of a duplication process yielding a direct positive image. The image is frequently deep blue, purple, black, or brown on a near-white ground. The ground edges often are stained yellow-brown (though not on the verso) and the paper embrittled due to oxidation and residual chemicals. Fibers will be visible under low magnification. May possess an ammonia odor and a tendency to curl if the support is thin, coated paper. Sheets will have a tendency to curl slightly. A diazo print is an azo dye image reproduction of a document or, more often, a technical line drawing (see Architectural Drawing Reproduction).

- Composition

-

Support Image/Text Paper (uncoated or coated) Azo dyes - Deterioration

- Due to residual chemicals, the paper will likely be embrittled. Edges will appear yellow-brown on the recto, but not on the verso. The azo dye-based image/text may be faded, particularly if housed in an acidic enclosure/environment at any point, but also if exposed to light for an extended period. Residual chemicals and light exposure can—in tandem—cause yellowish-brown discoloration in unexposed areas. Diazo prints must be stored separately from most photographic materials due to destructive off-gassing. Alkaline storage enclosures are not advised for diazos.

- Risk Level

- Moderately high (older prints are at higher risk). All diazo prints should be assumed fragile and volatile. Diazos often contain residual chemicals harmful to themselves and other materials stored in proximity. They are also known to transfer color dyes to adjacent papers. Diazo prints should therefore be stored separately from other materials if possible. Alkaline storage enclosures are not advised for diazos.

- Process

- The various machines and processes used to create diazo prints all differ slightly but were essentially based on the same chemistry. The copy paper was coated with a sensitizing solution containing a diazo compound and a coupler compound in addition to other additives (i.e. optical brighteners). Depending on the coupler, the image/text color varied. Copies were often produced from a master made of a translucent plastic or paper material typed upon using a typewriter with special ink impermeable to UV radiation. This master was used like a photographic negative, in which light is blocked in text (dark) areas and allowed to pass through non-text (light) areas. The actual copy process was carried out using a specialized copy machine, which housed a strong UV light source and developing unit. The master and sensitized copy paper were inserted together into the copy machine and exposed to the UV light, which broke down the diazonium compounds in the copy paper. This prevented the formation of dye in the exposed areas during the development process, thus producing a positive image in the unexposed areas.

- Background

- While diazo prints were made as early as the 1880s, the process was not widely commercially used until the 1930s. The process was primarily used for copying large-scale drawings beginning in the 1920s. Diazo prints replaced the cyanotype (blueprint) in the engineering and architectural design spheres. The office copy application was far less common, used from the 1940s through the 1970s, primarily in Europe. Machines and papers were produced by companies such as Ilford and Ozalid.

- Storage Environment

-

Cool storage (below 50 degrees) is recommended, and colder is generally better. Allowable Fluctuation: ±2°F; ±3% RH

Temp. 35–65°F (2–18°C) RH 35–50% RH - Storage Enclosure(s)

- Loose, unbound records should be stored in acid-free file folders. Alkaline storage enclosures are not advised for diazo prints. Folders should be placed in acid-free or low-lignin archival boxes. Alternatively, folders may be stored in steel filing cabinets with a baked enamel finish. Care must be taken not to overfill folders and boxes. Documents should fit easily in folders and boxes; they should not be forced into enclosures that are too small. Spacer boards, which can be created using scored and folded acid-free board, may be placed in underfilled boxes to prevent folders from slumping or bending.

- Storage Orientation

- Diazo prints should be stored vertically in file folders, which are placed vertically inside acid-free storage boxes or steel filing cabinets.

- Display Recommendations

-